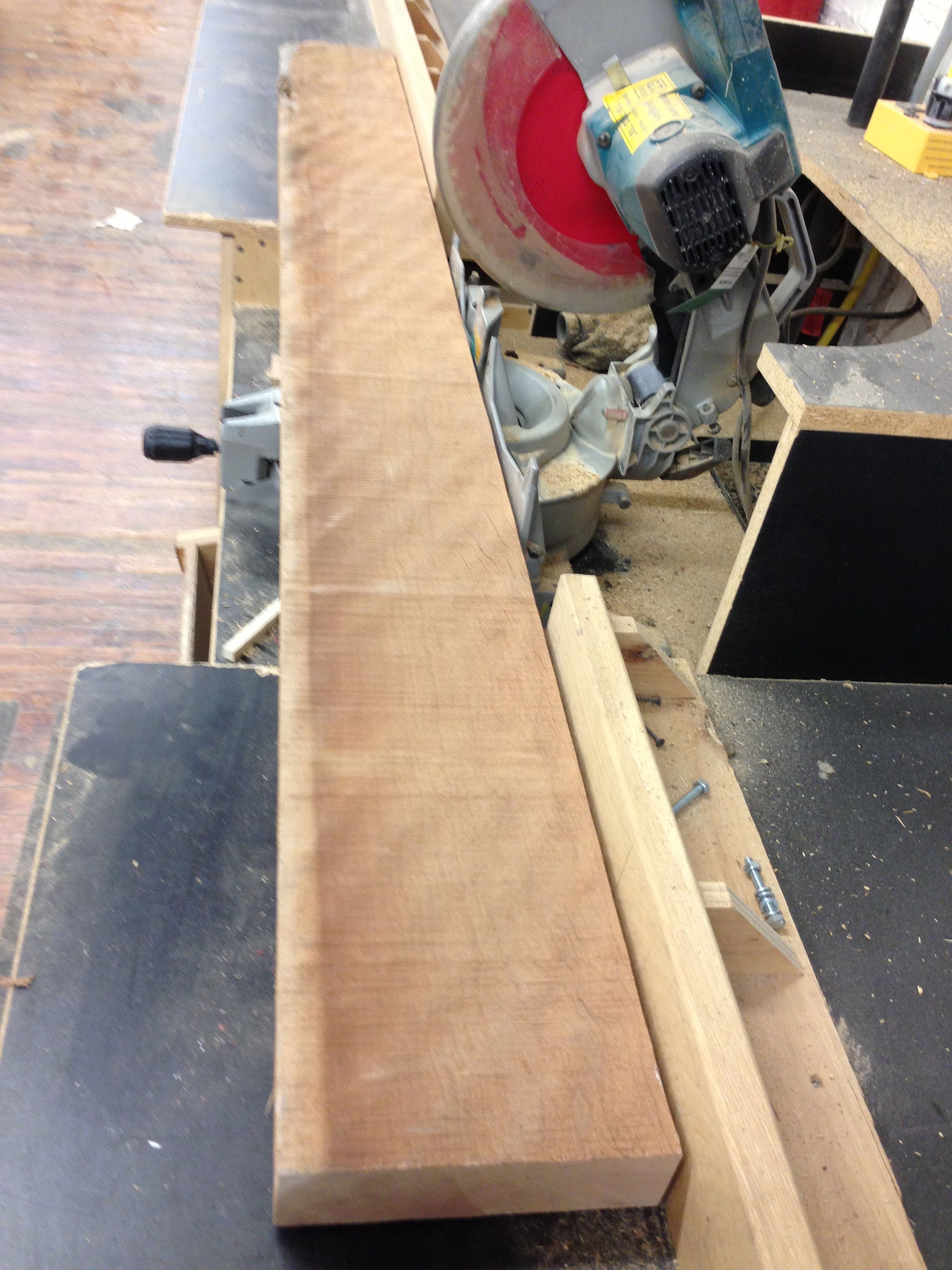

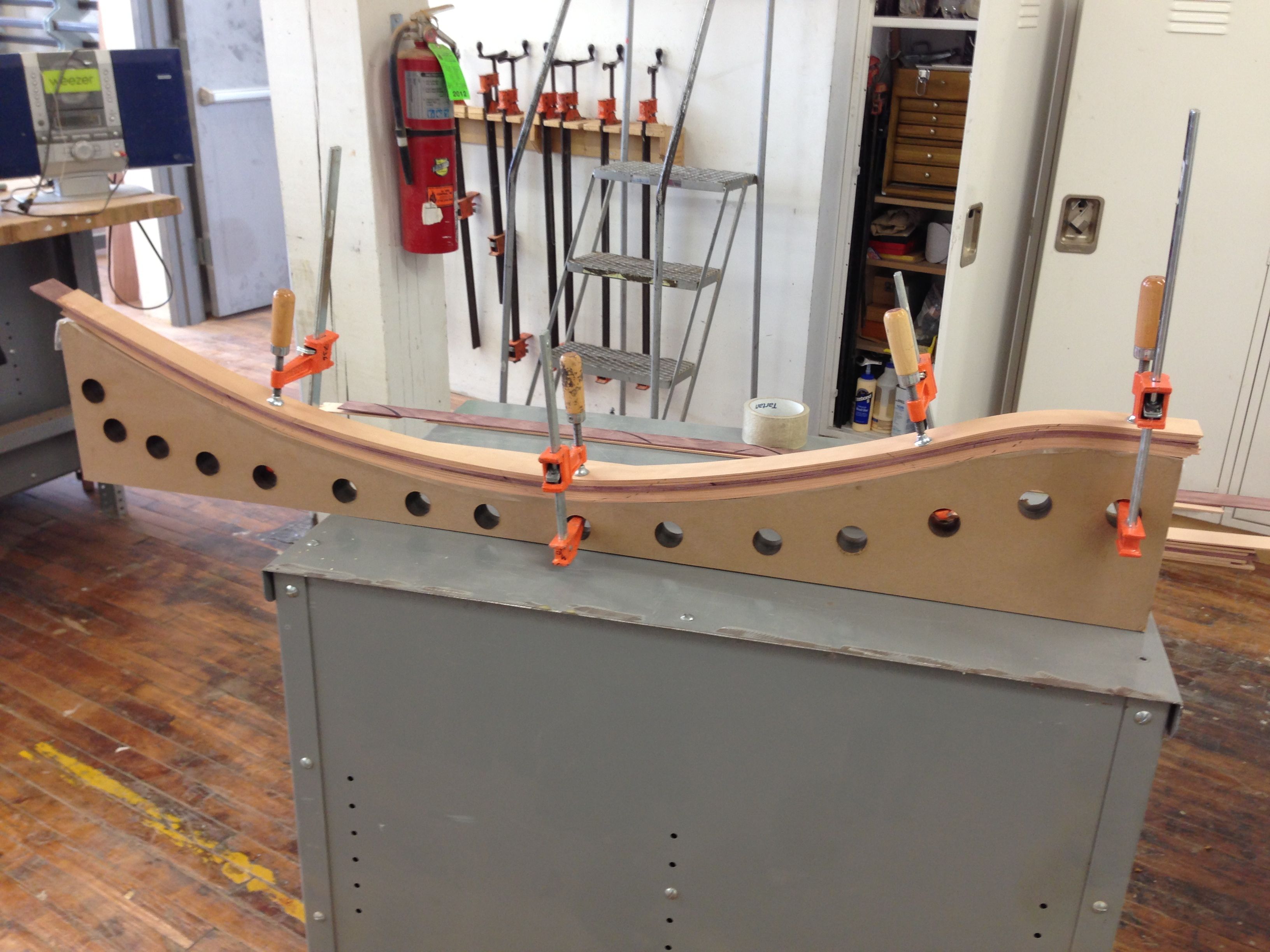

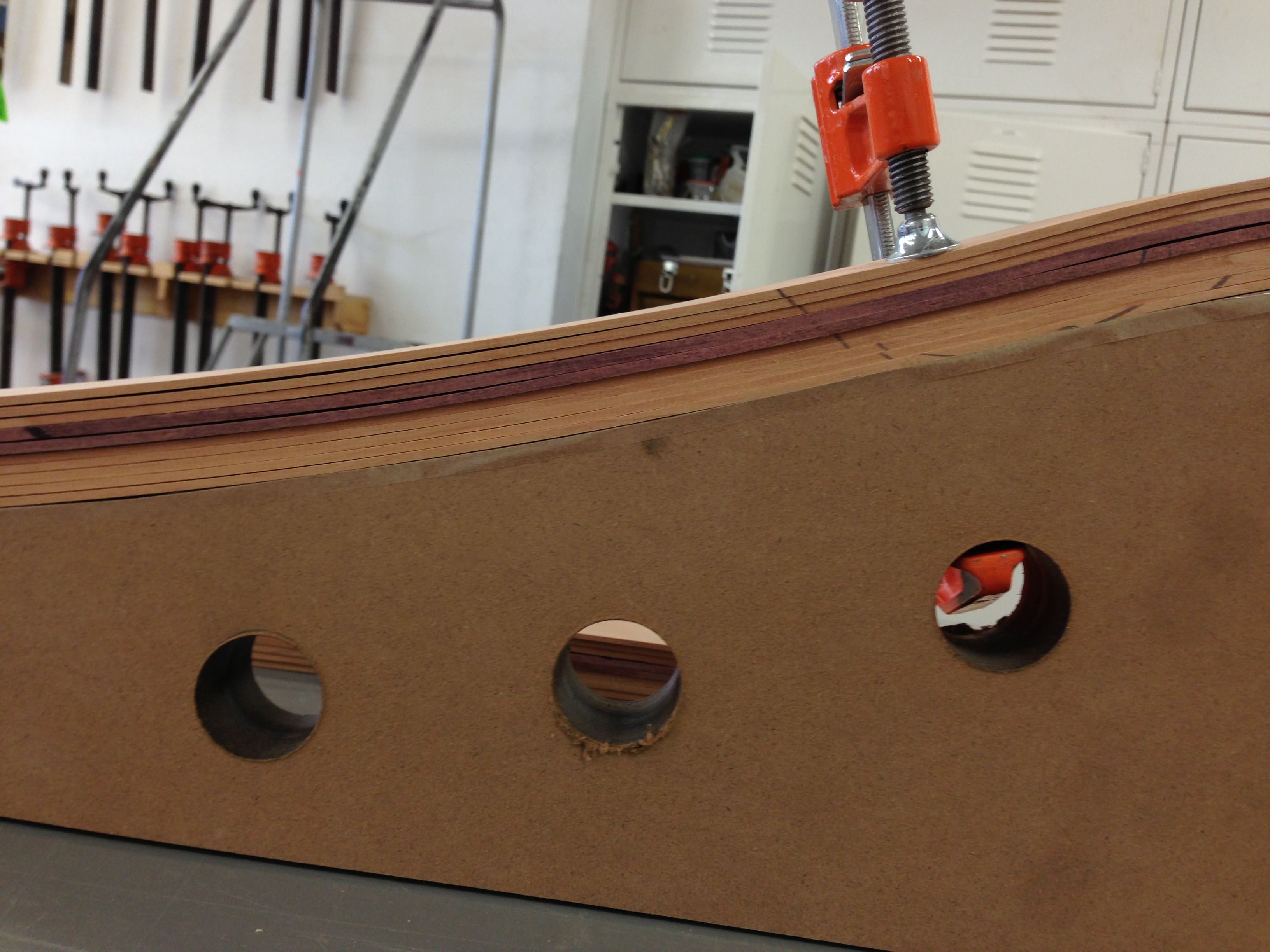

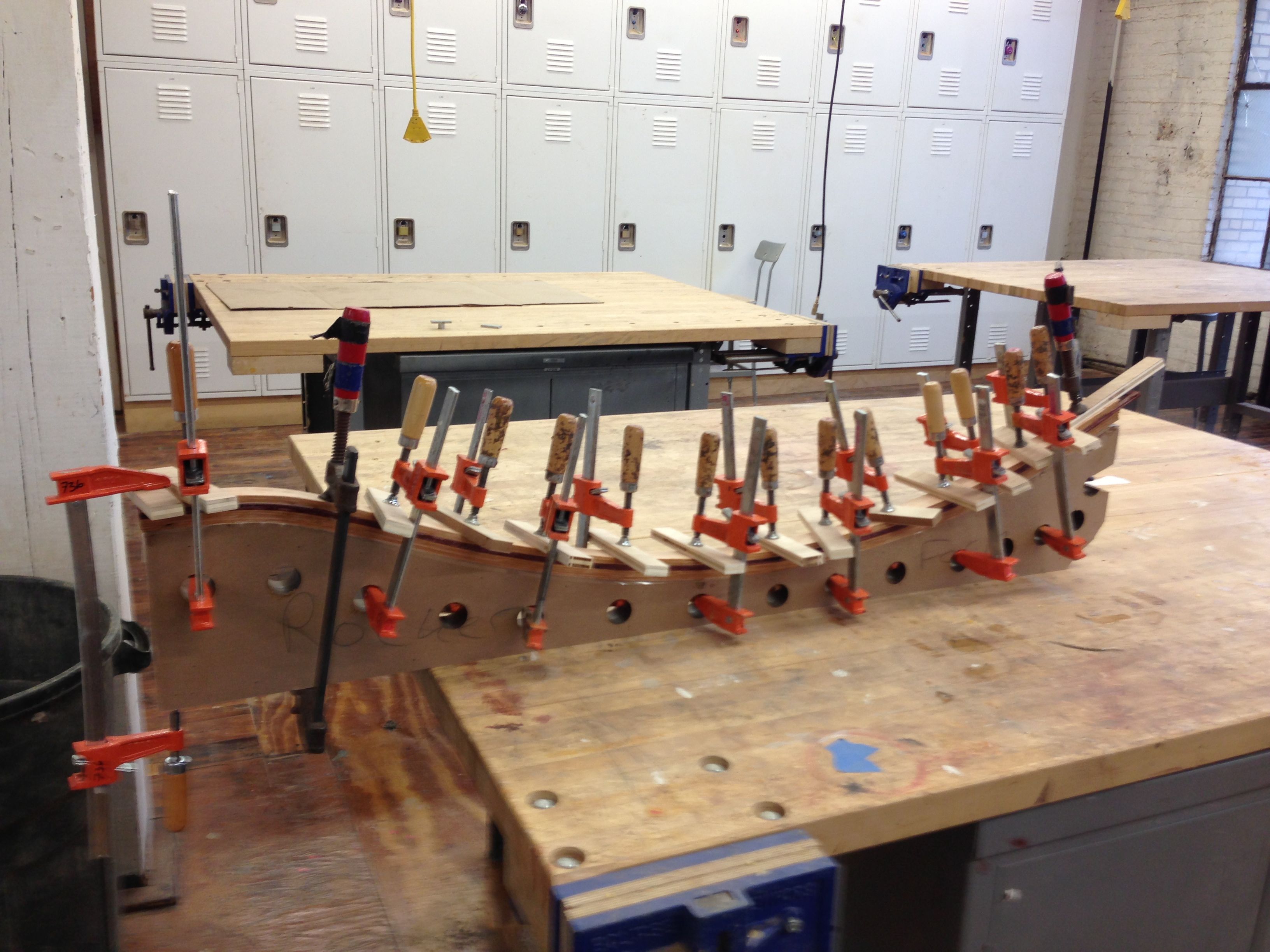

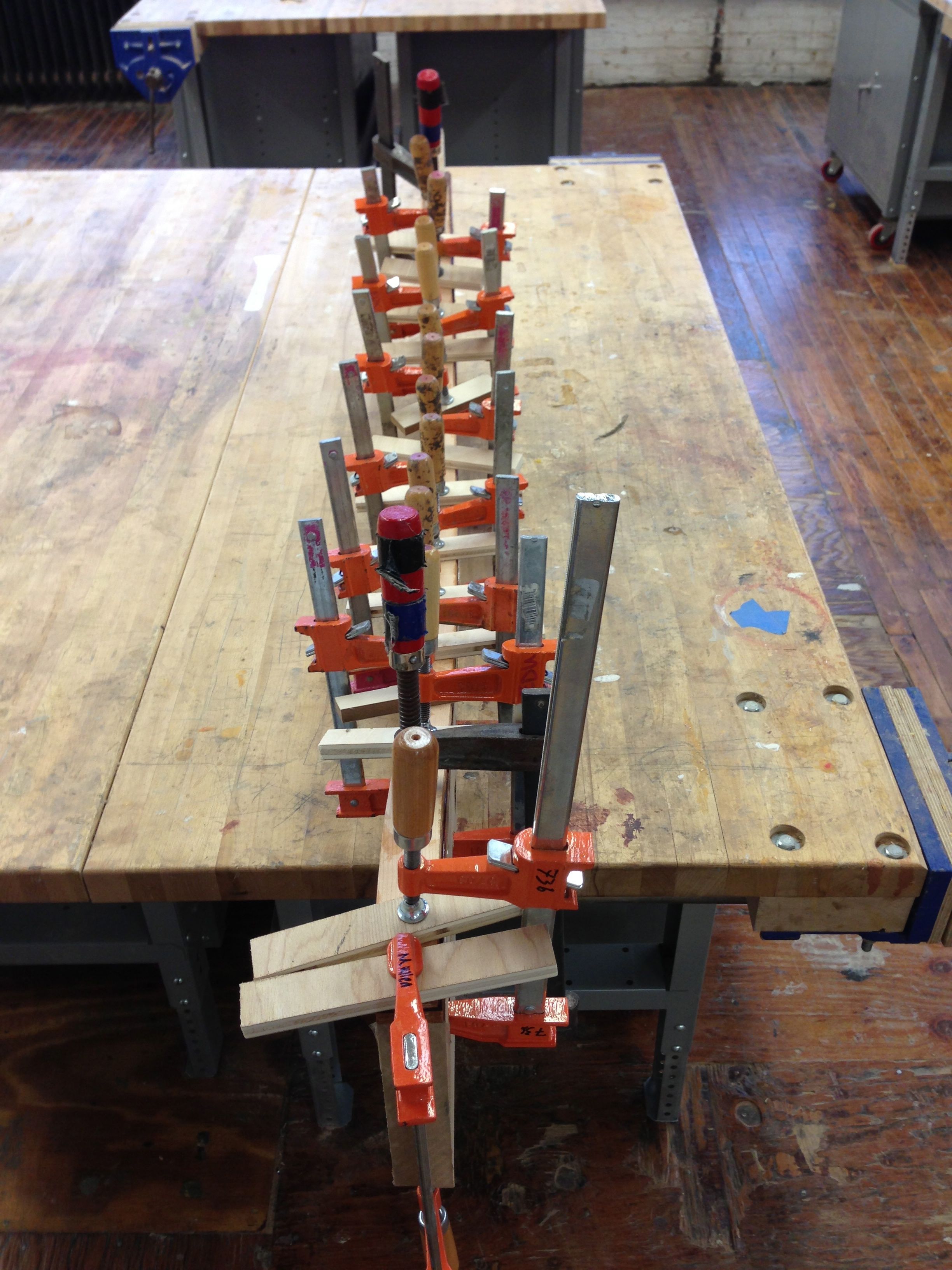

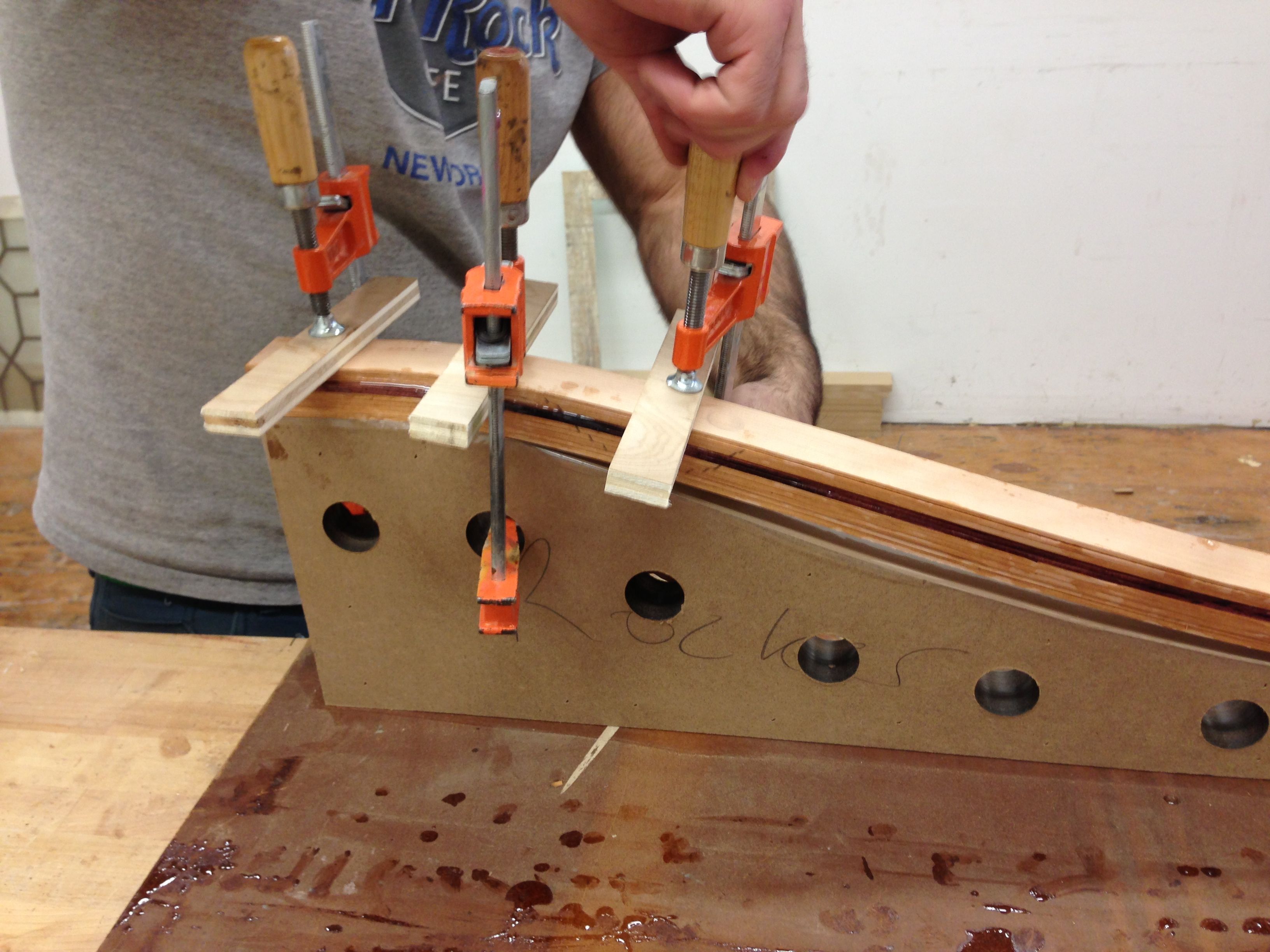

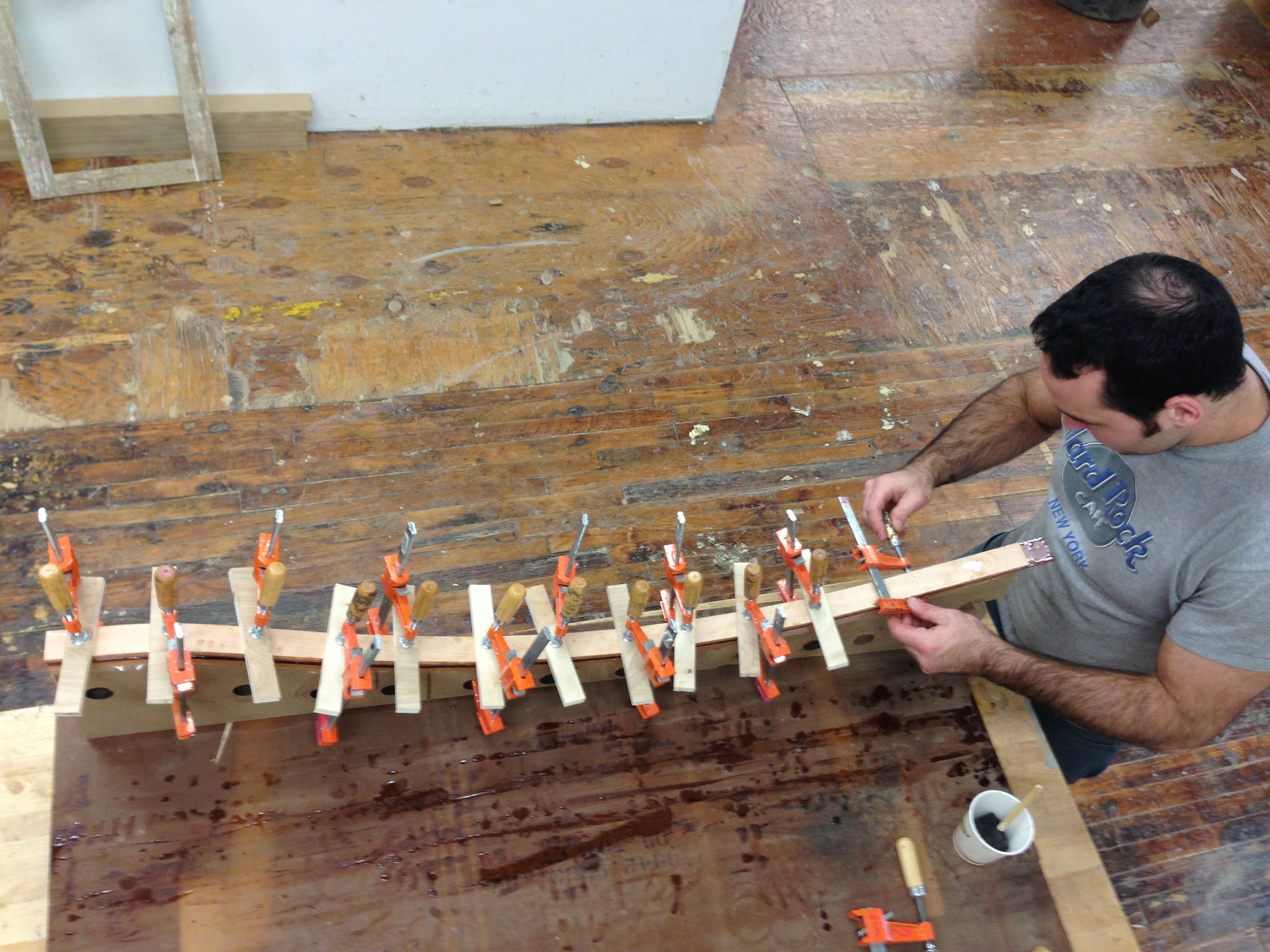

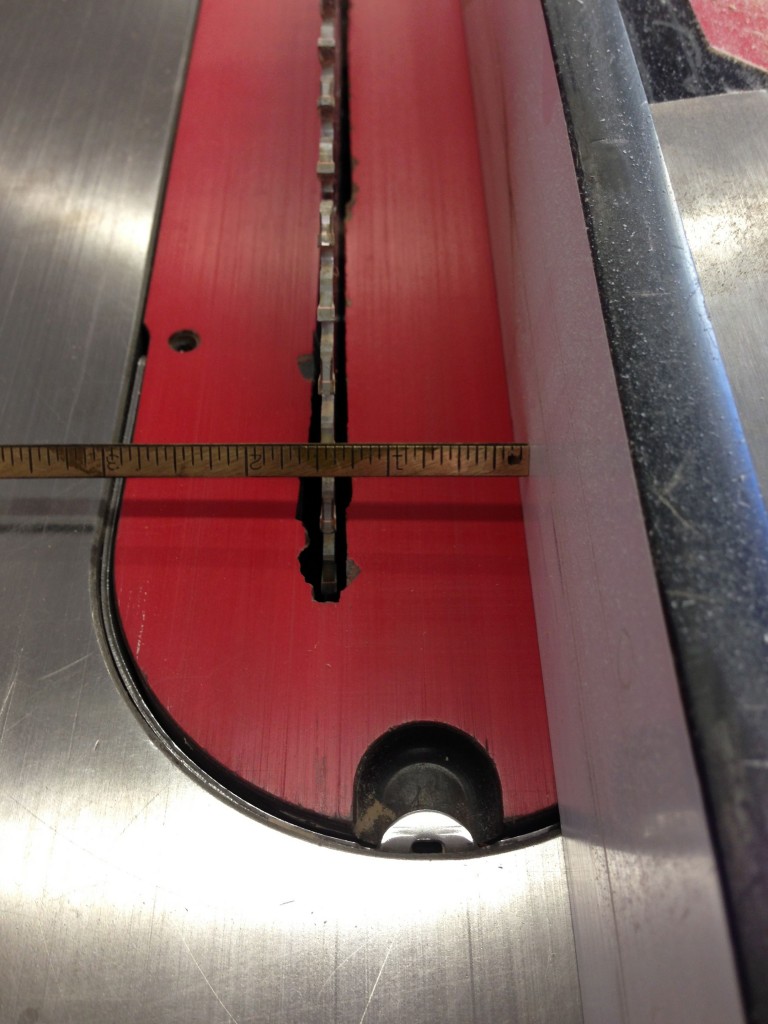

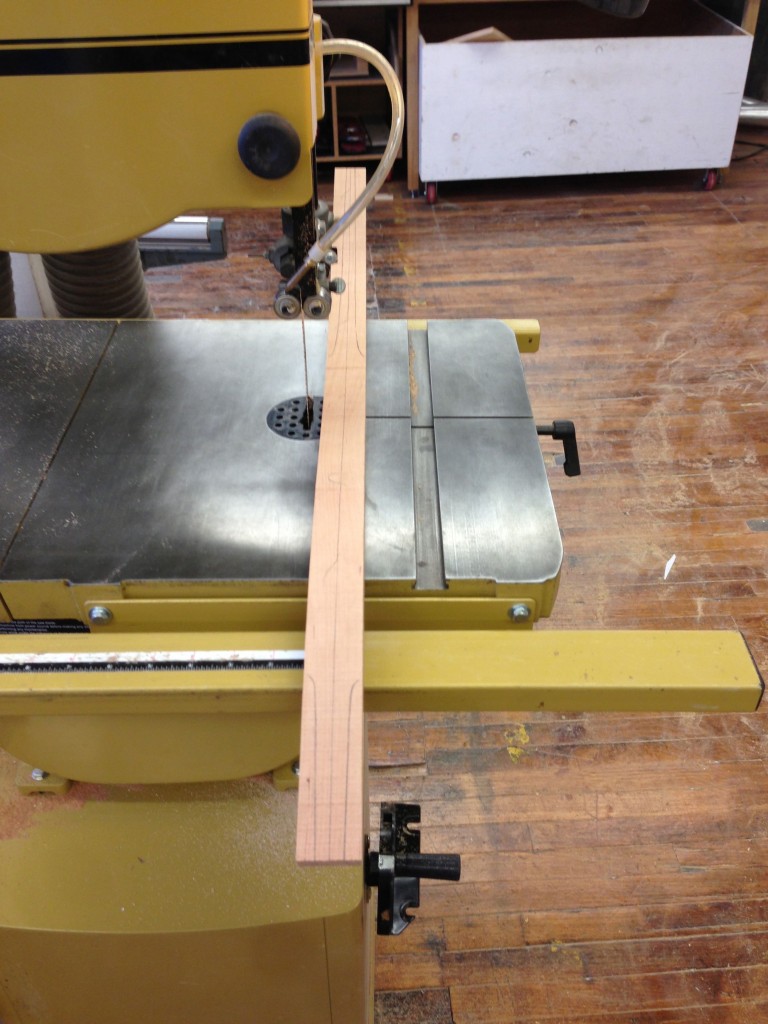

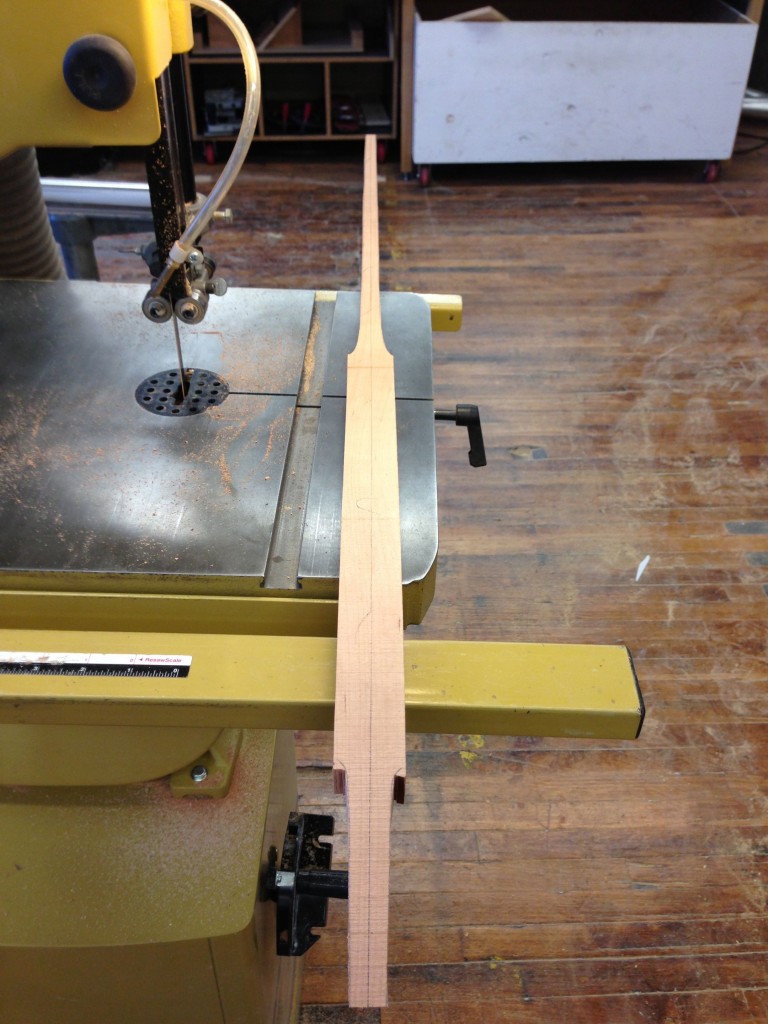

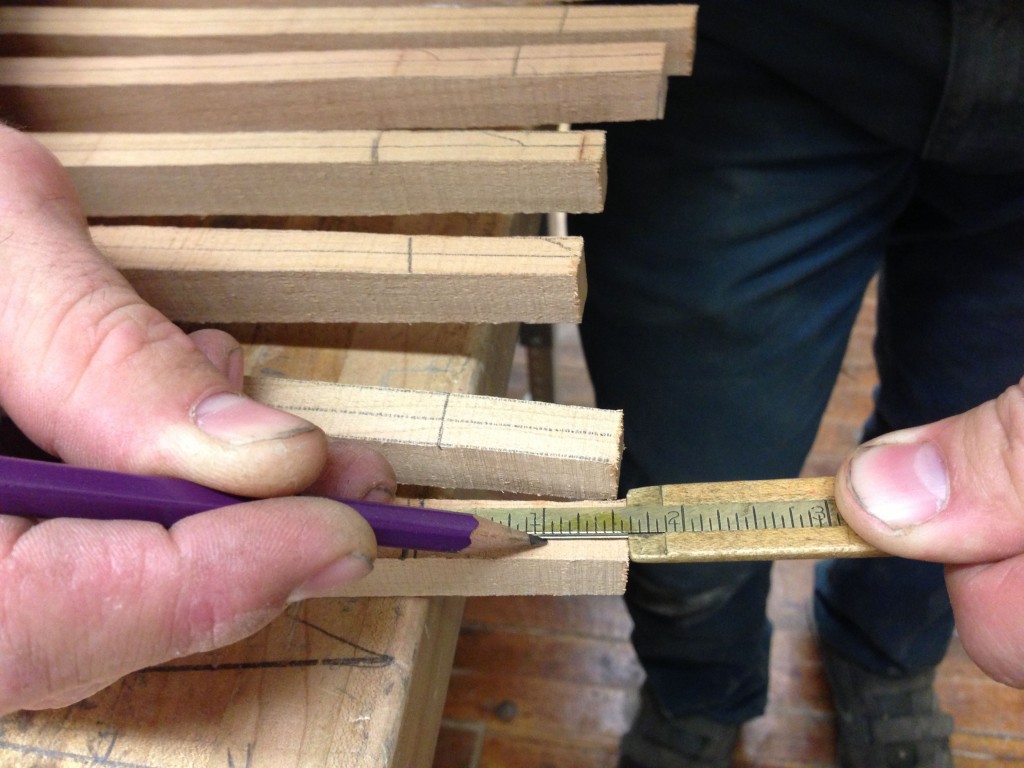

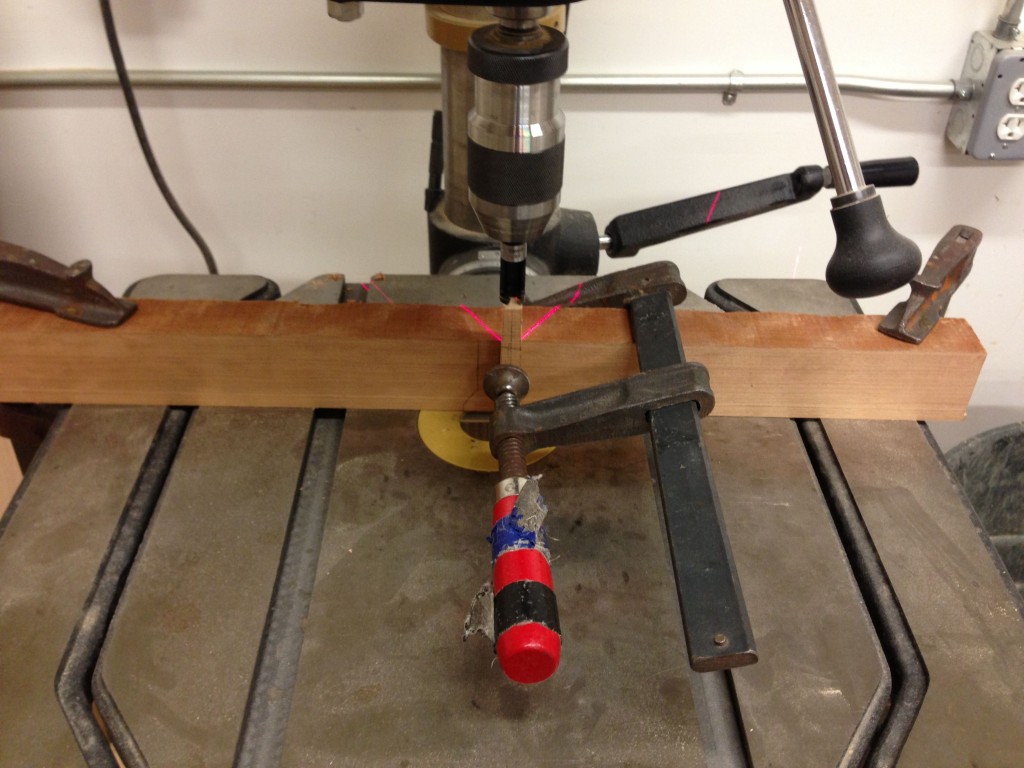

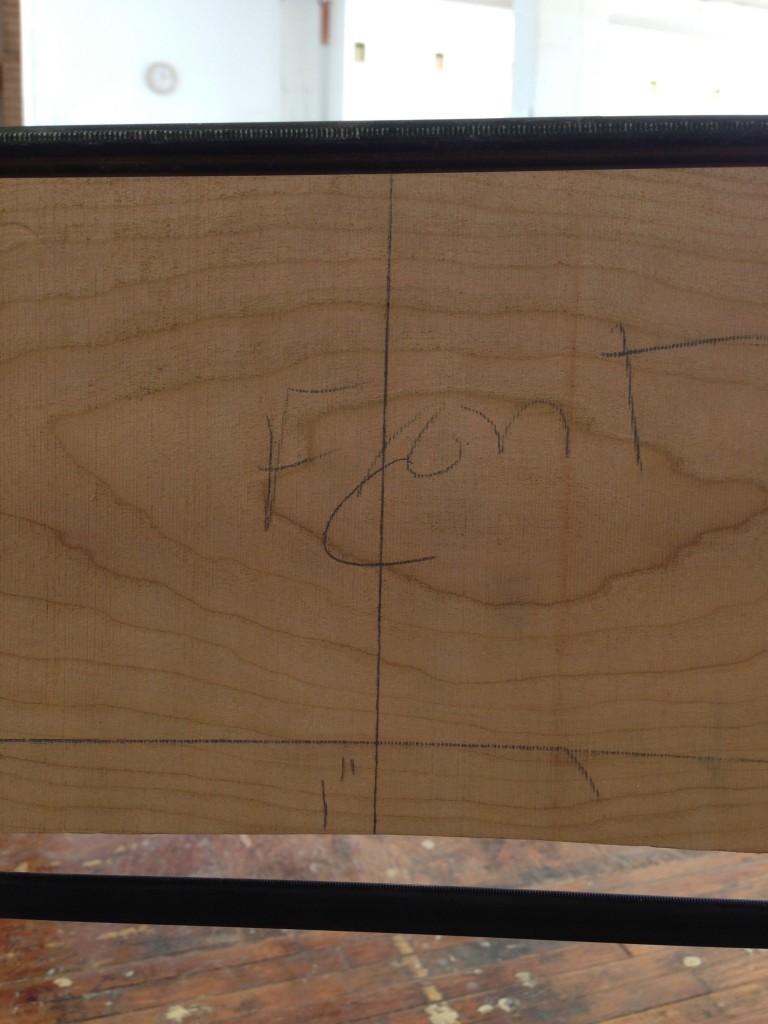

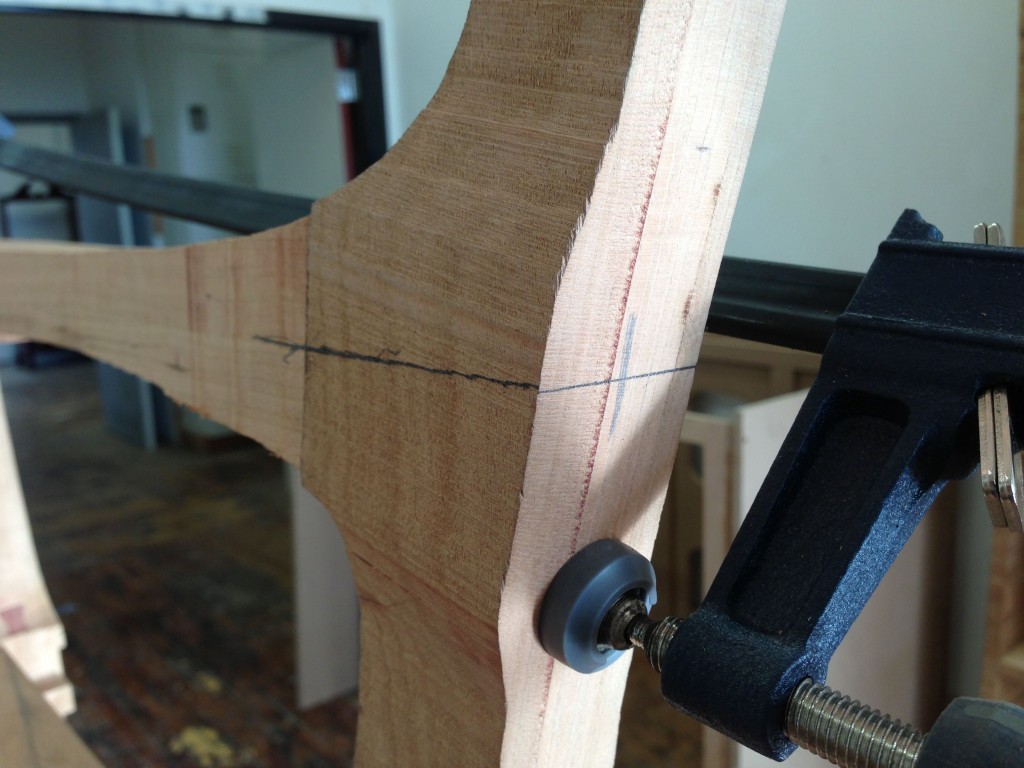

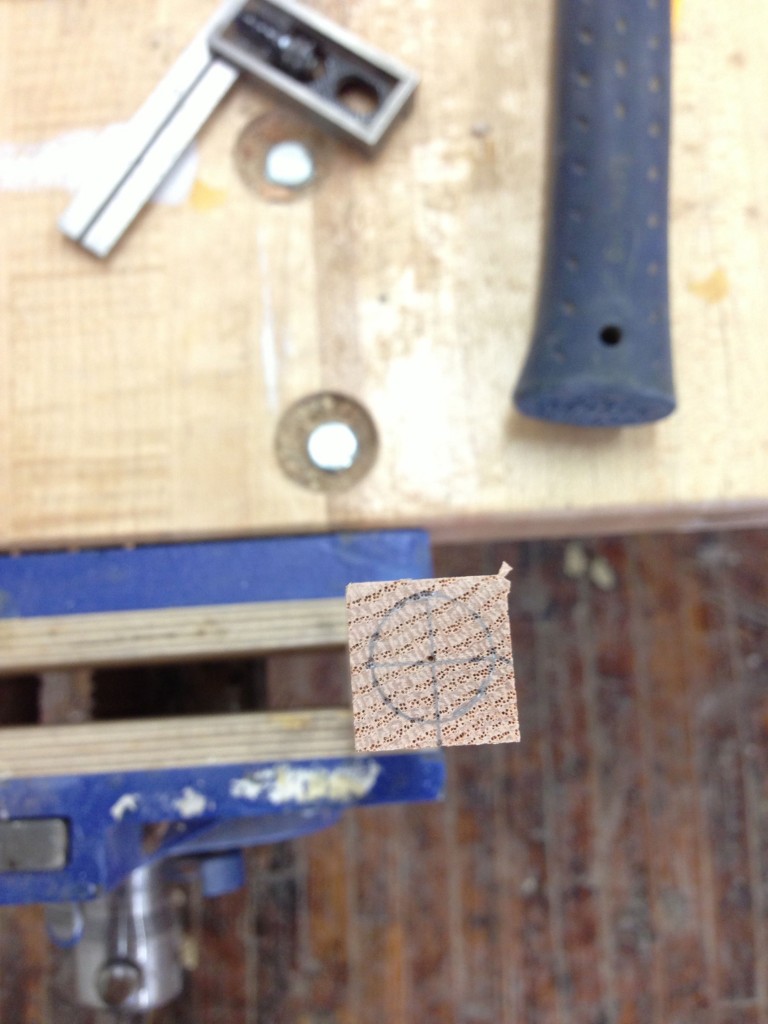

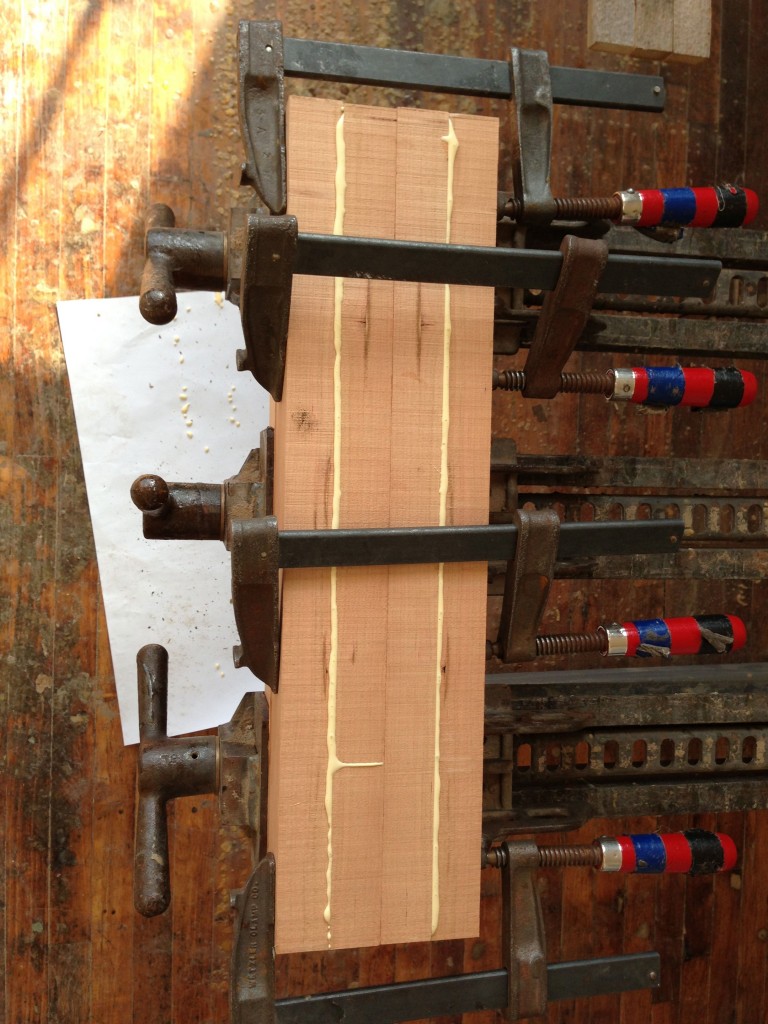

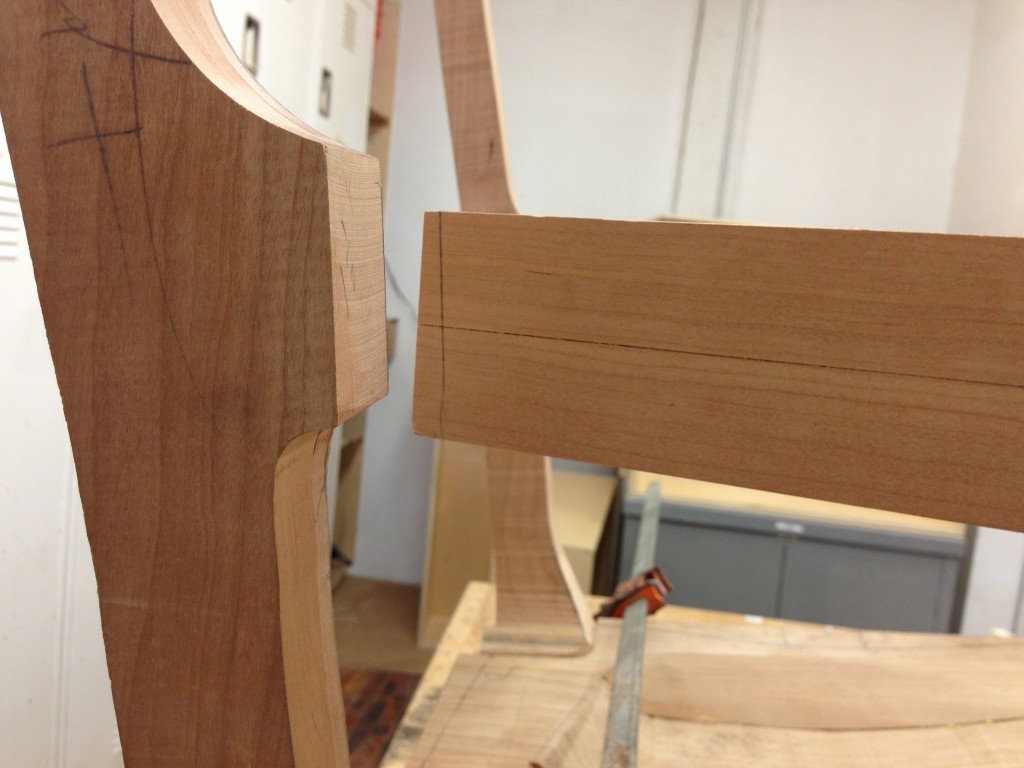

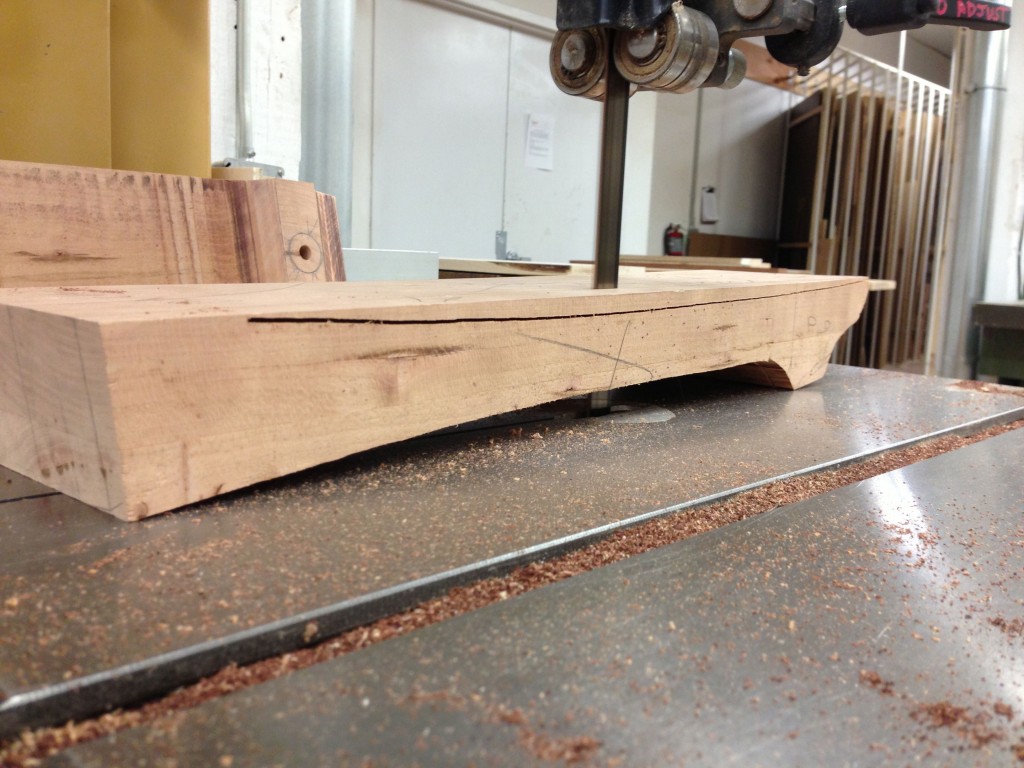

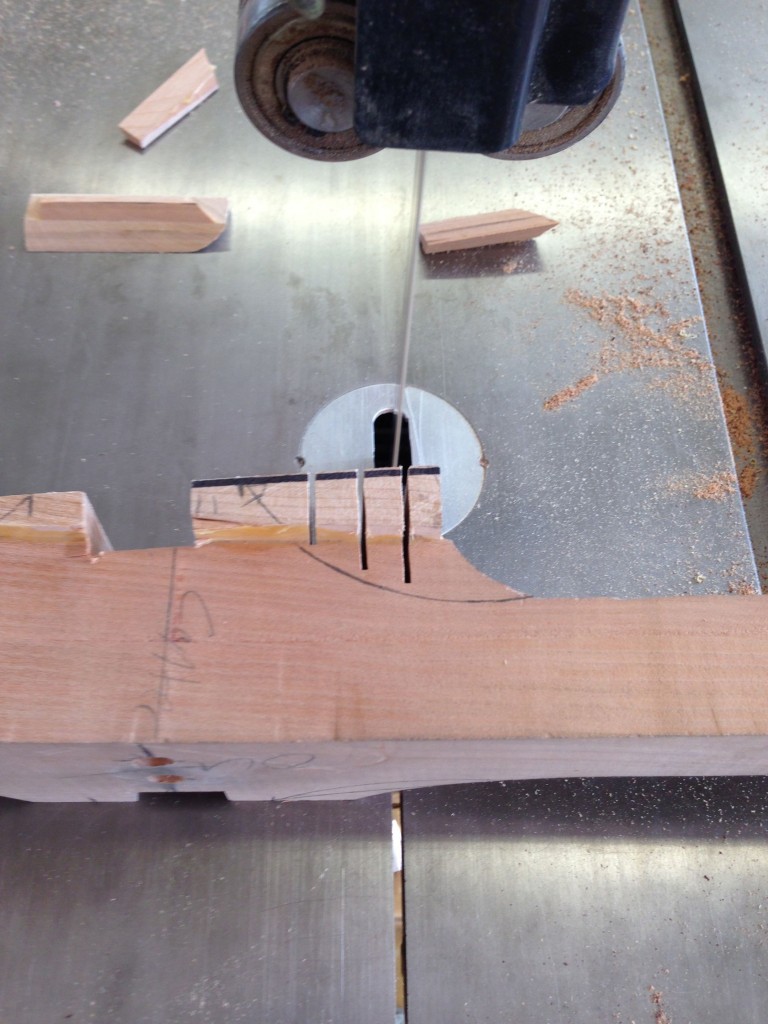

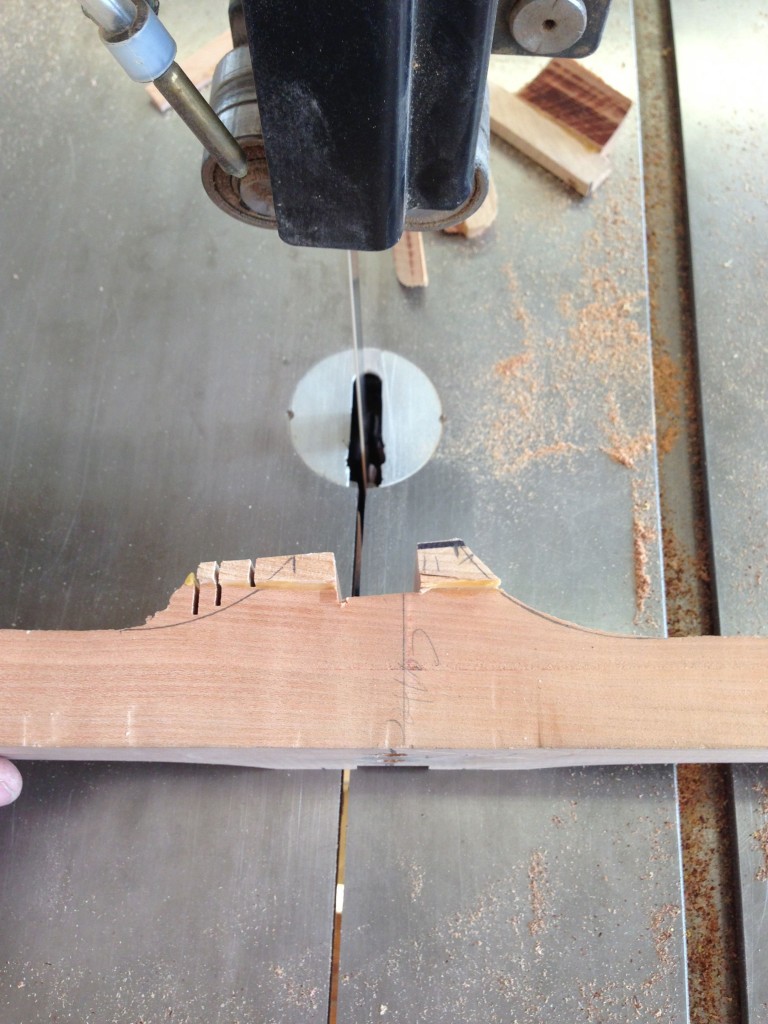

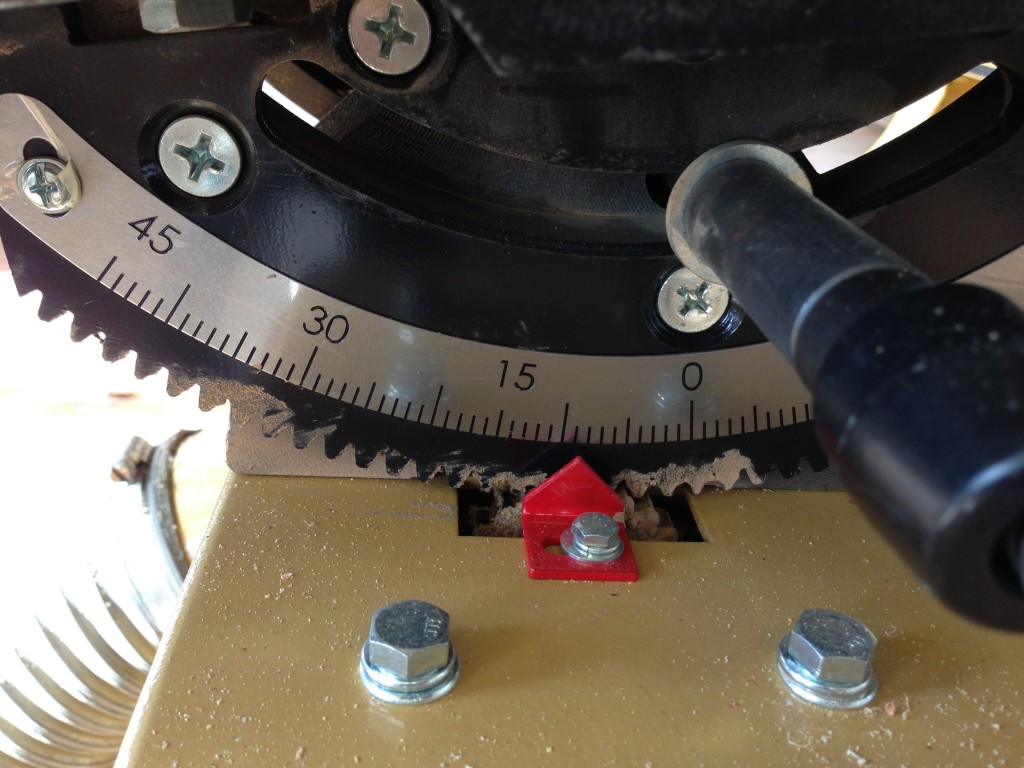

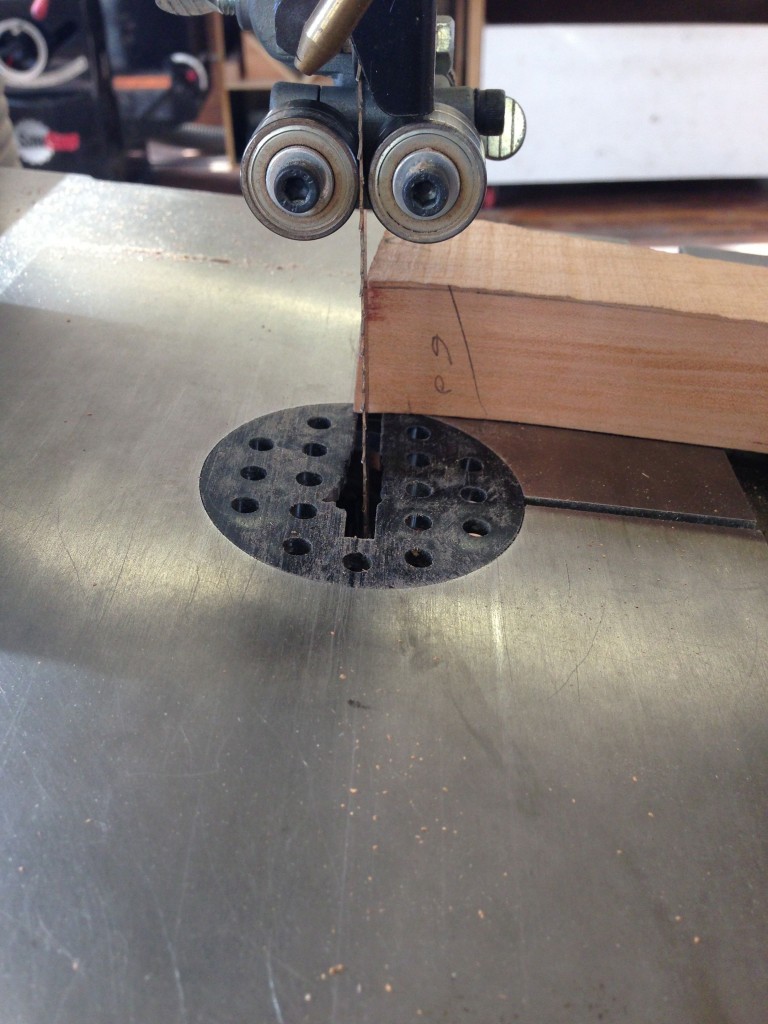

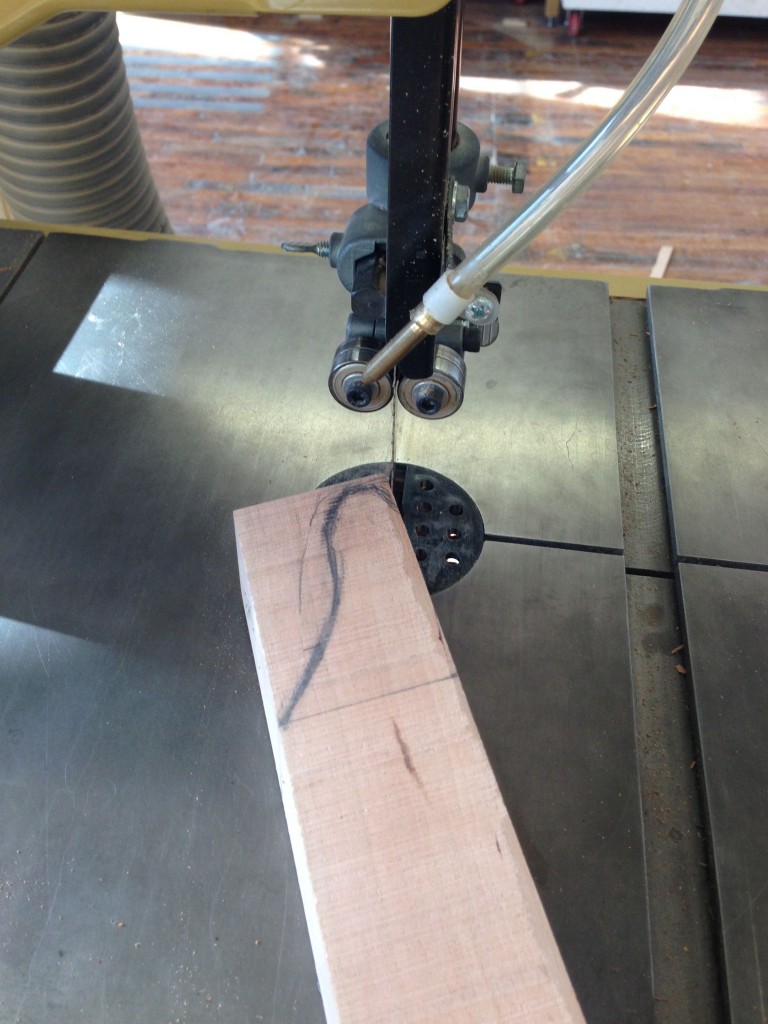

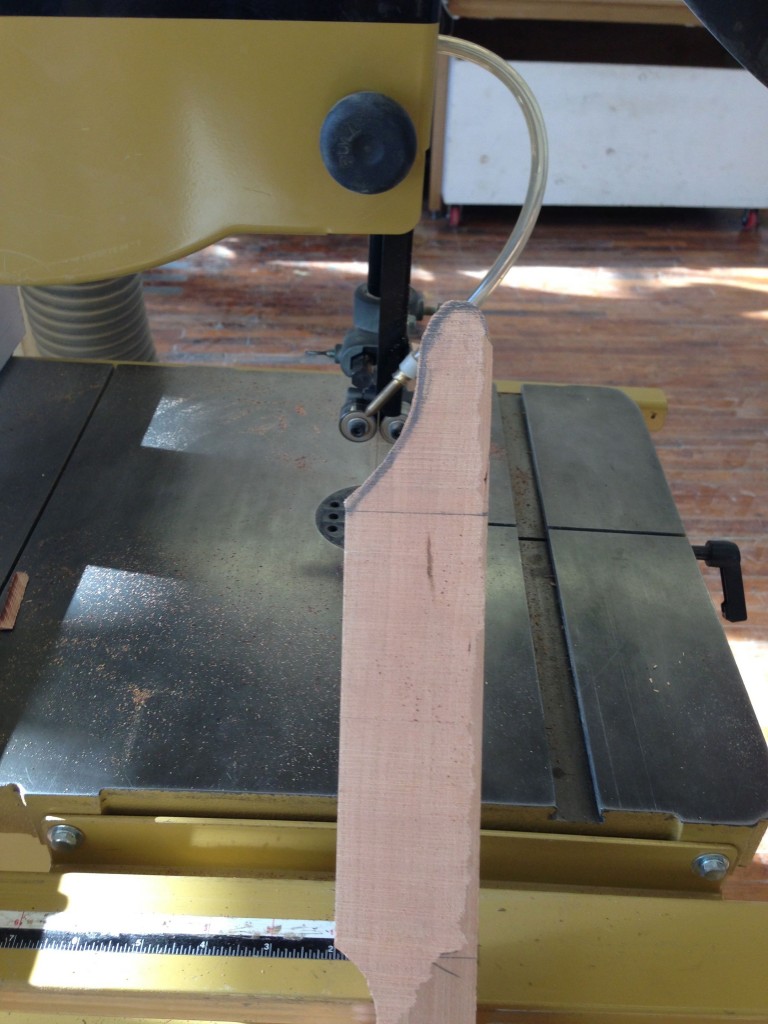

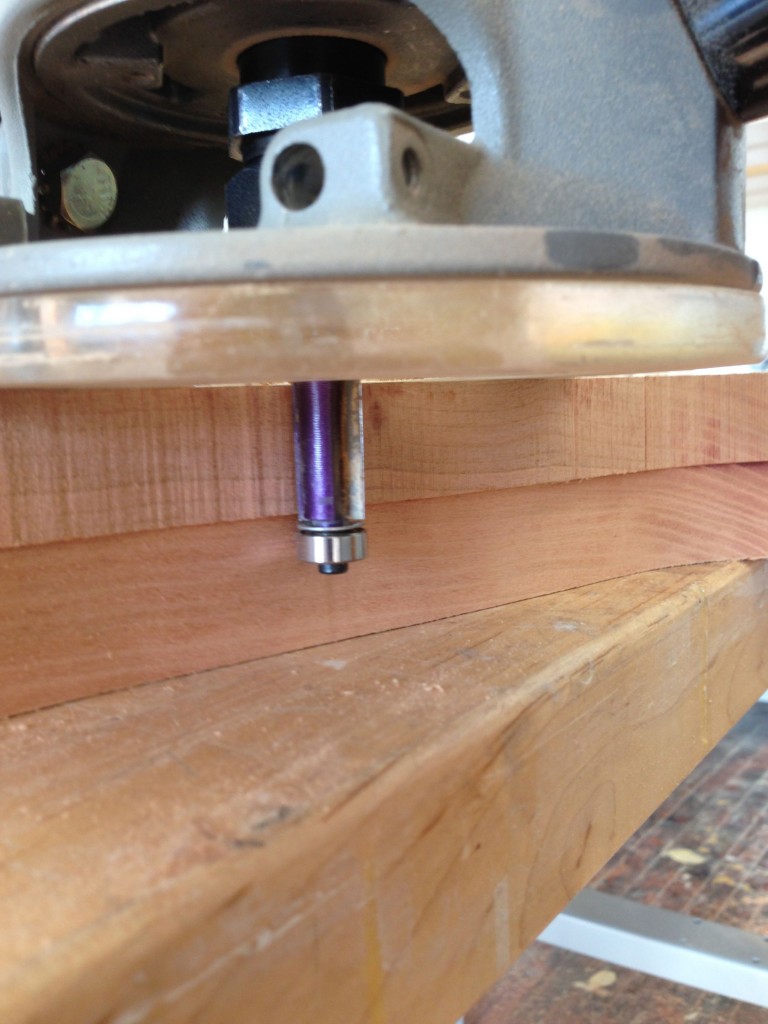

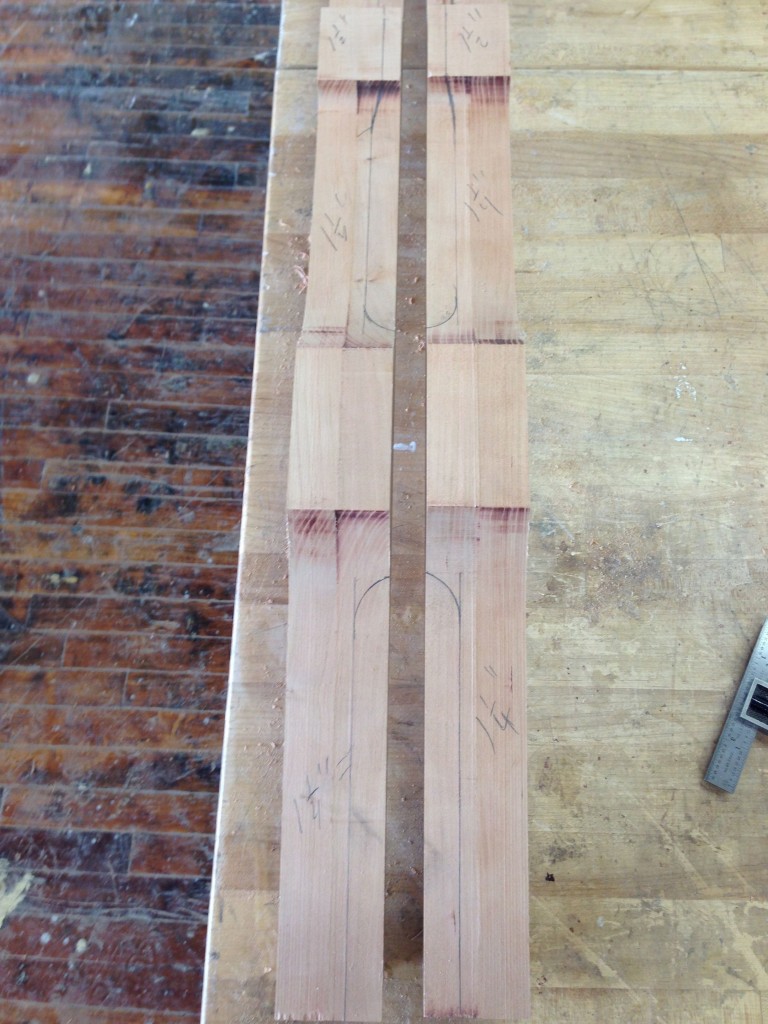

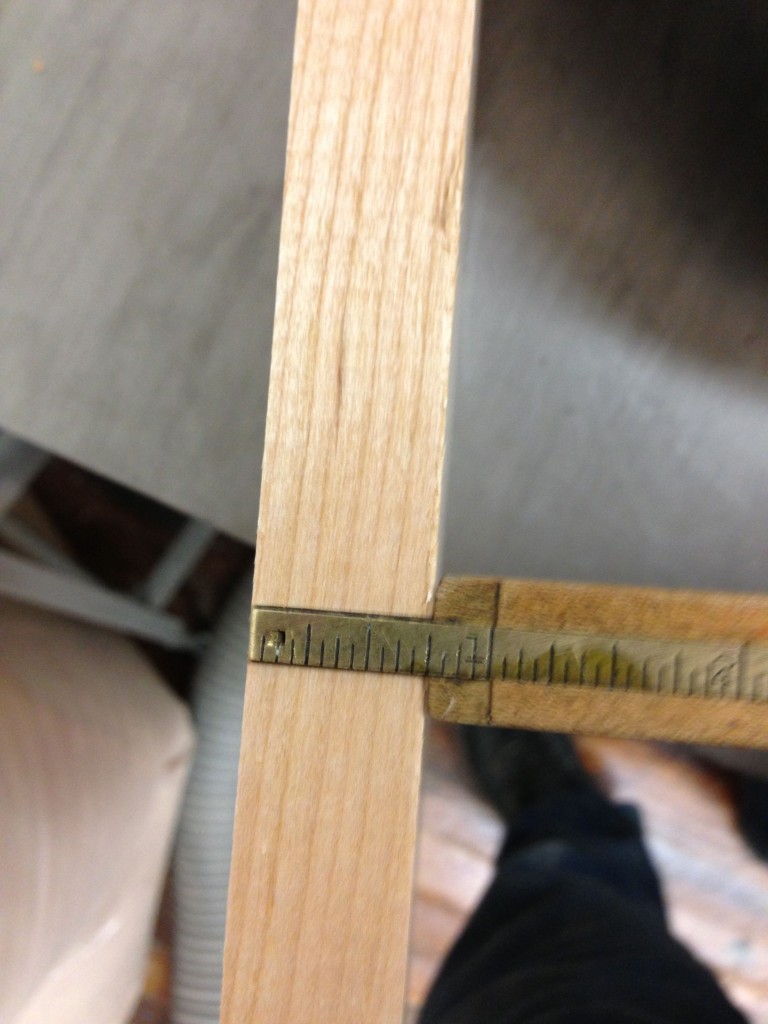

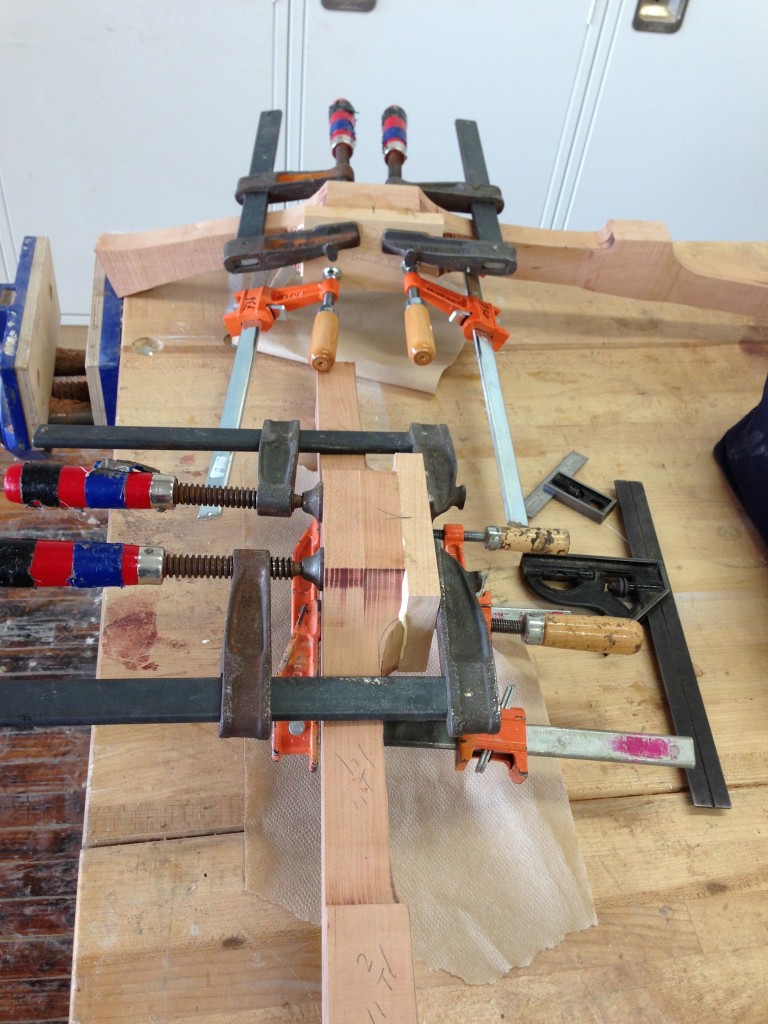

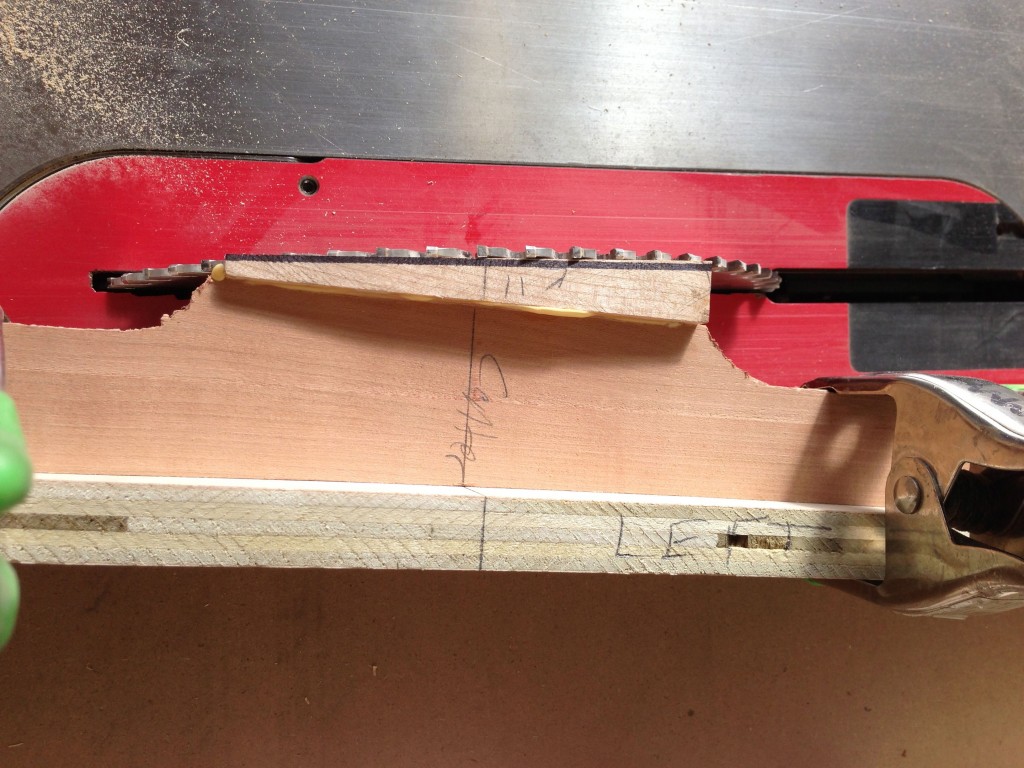

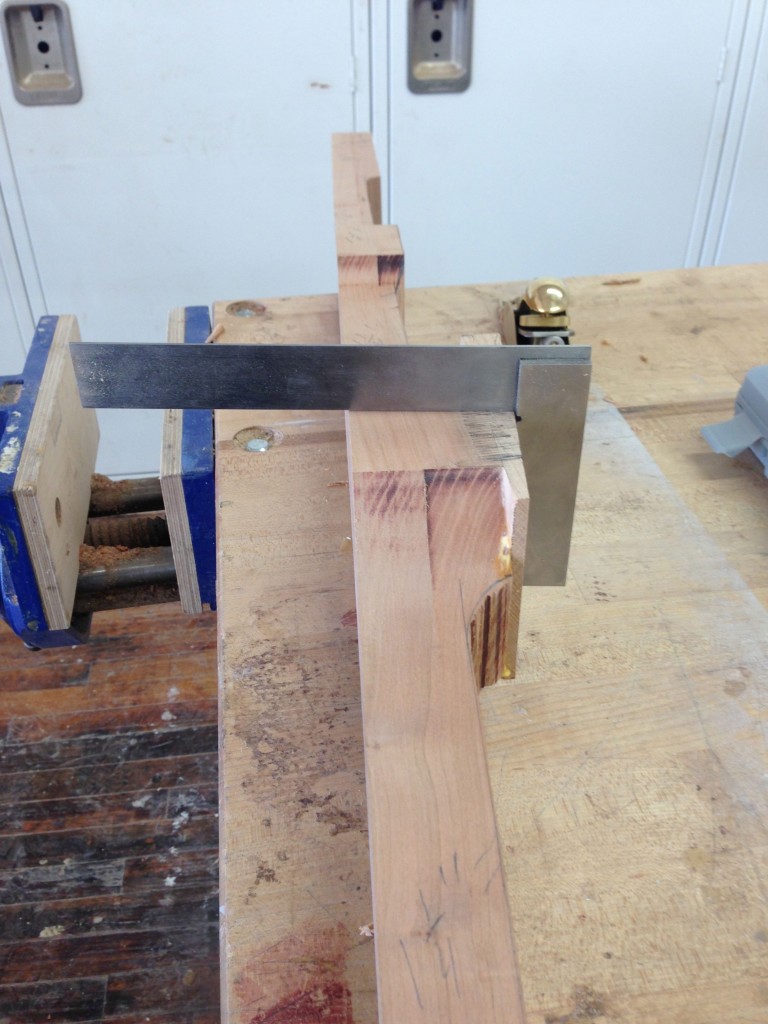

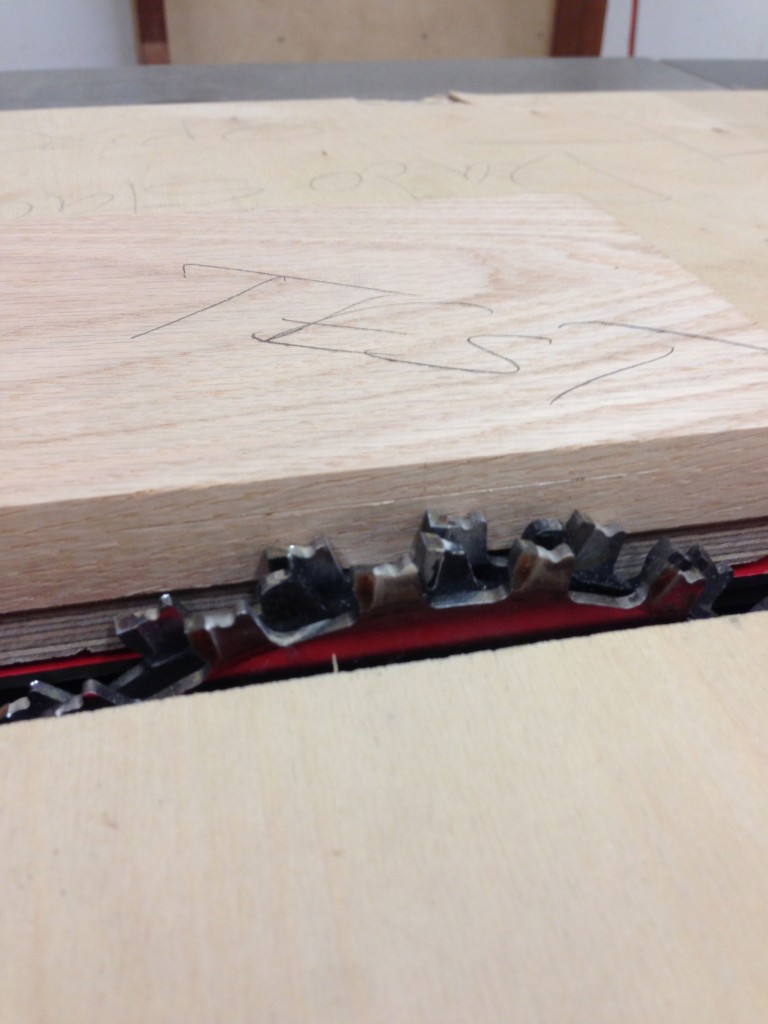

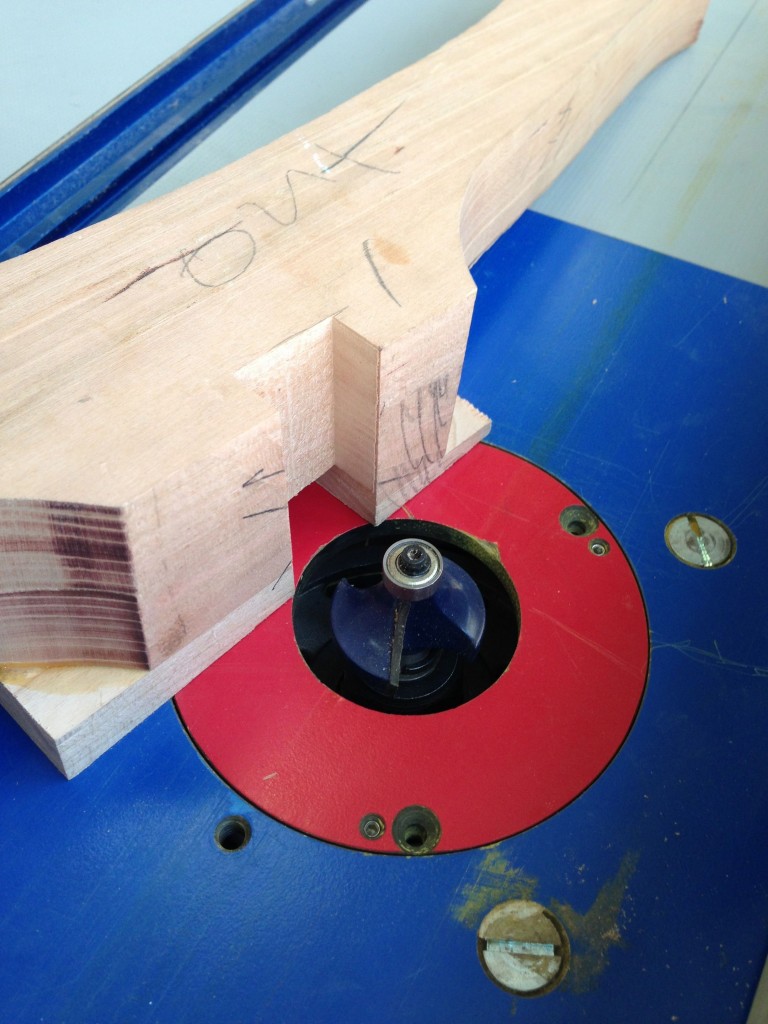

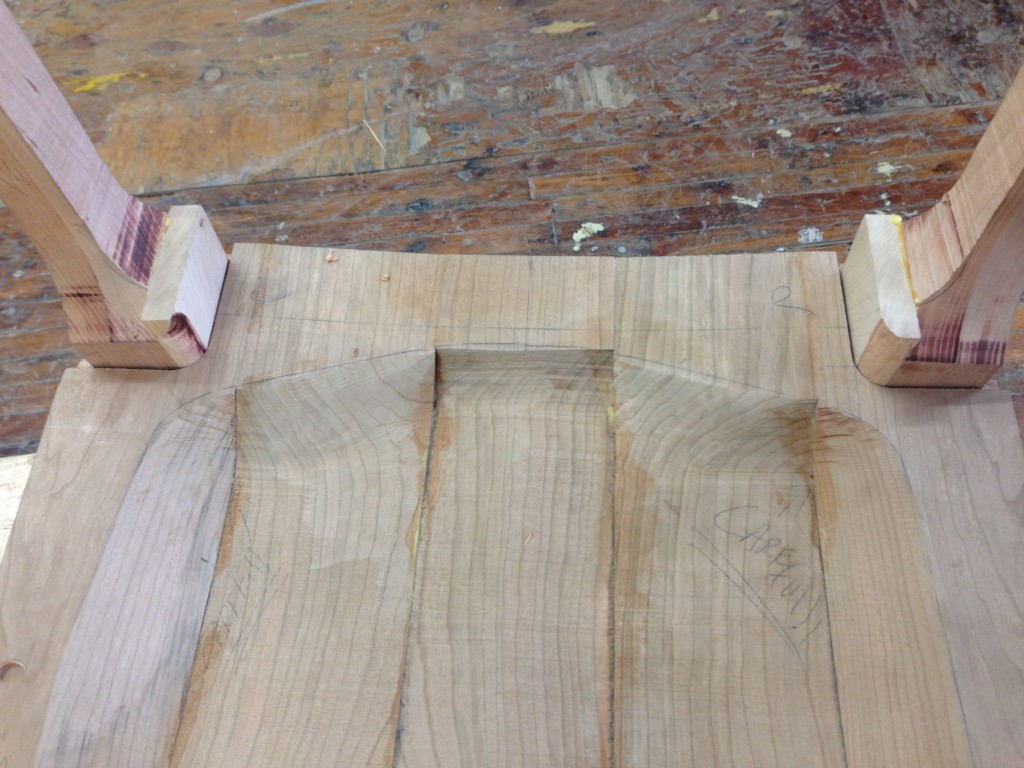

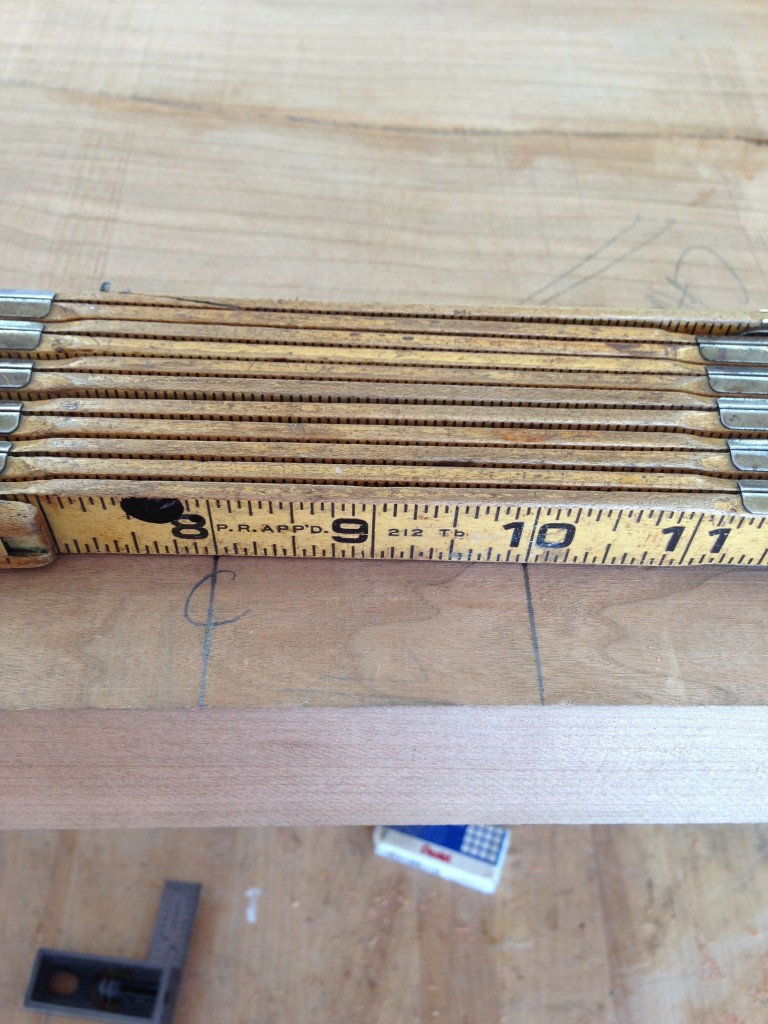

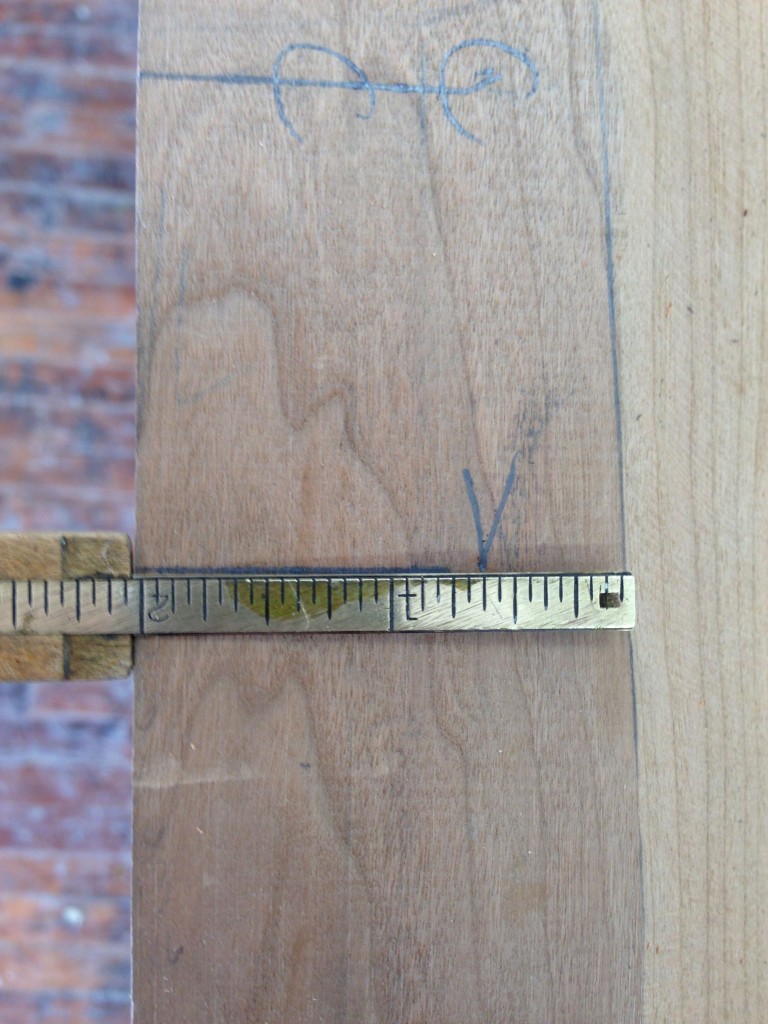

In order to create an arm with a deep sweeping profile and also meet the front leg and back leg joints, the stock needed to be 2 1/2″ thick or 10/4. The boards I purchased were only 8/4 requiring me to do a glue up to achieve the appropriate thickness. Instead of gluing two, 2″ thick boards together and cutting off a lot of waste, I decided to cut into one of my 10″+ boards to create 4, 5″ wide pieces. I then re-sawed them using the table saw to 1 5/16″. The picture gallery the will be posted next shows them being glued up and then jointed and planed to 2 1/2″. The arms are also book matched, meaning the two blanks were originally connected across their width as one 10″ wide board. Enjoy.