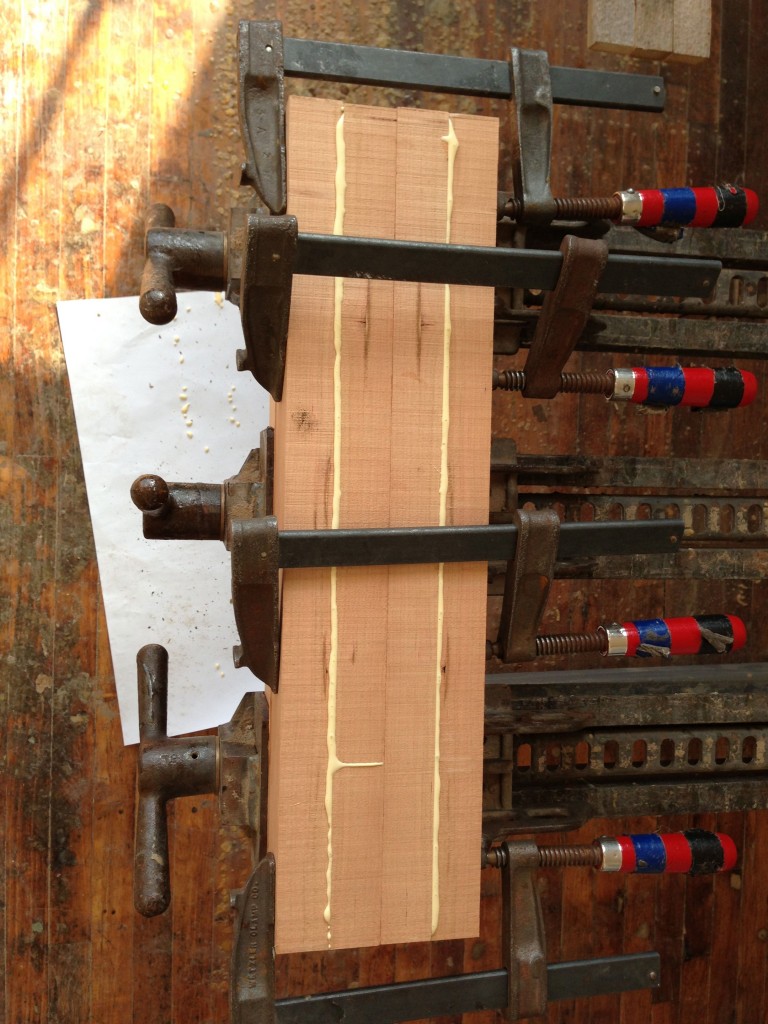

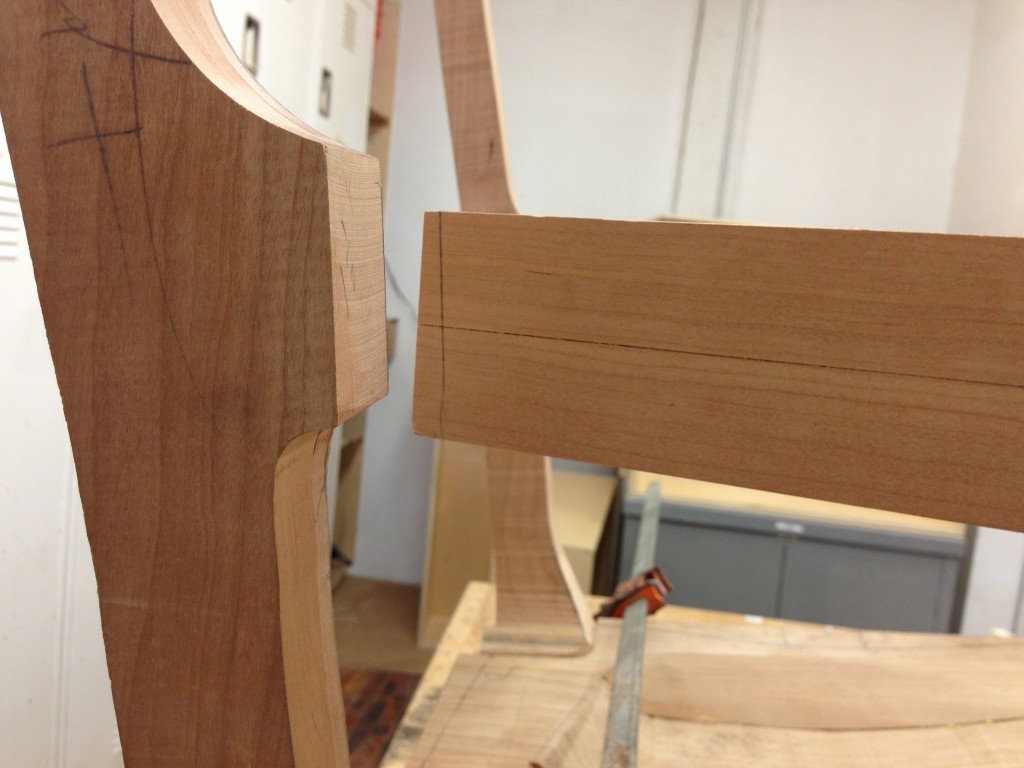

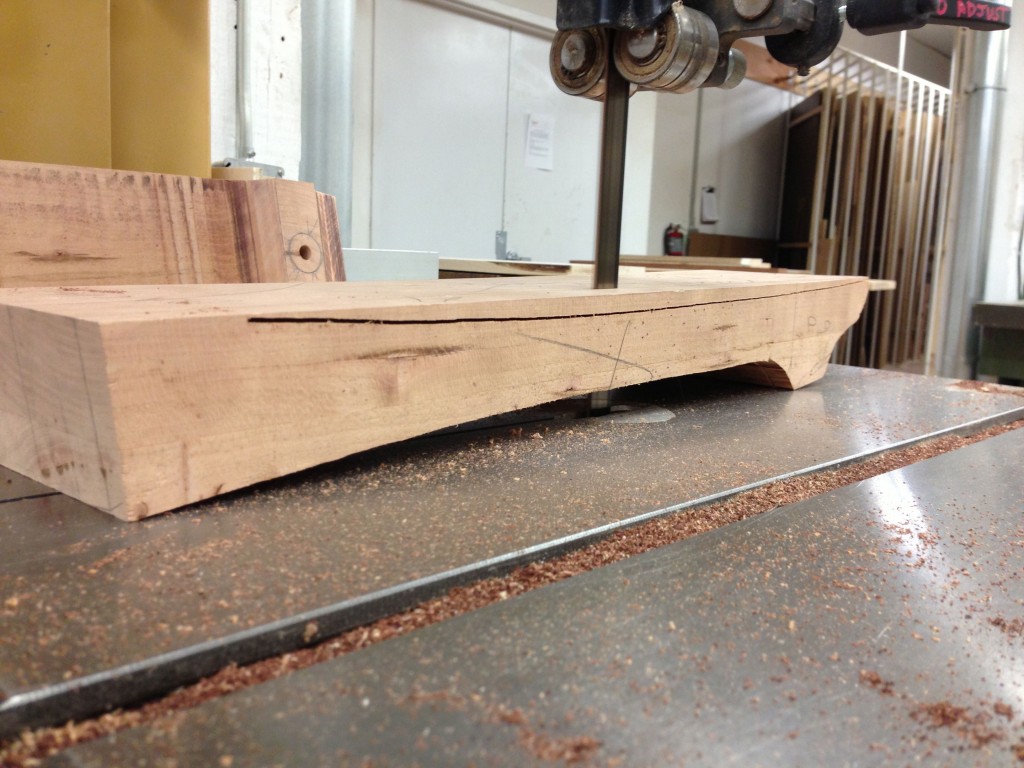

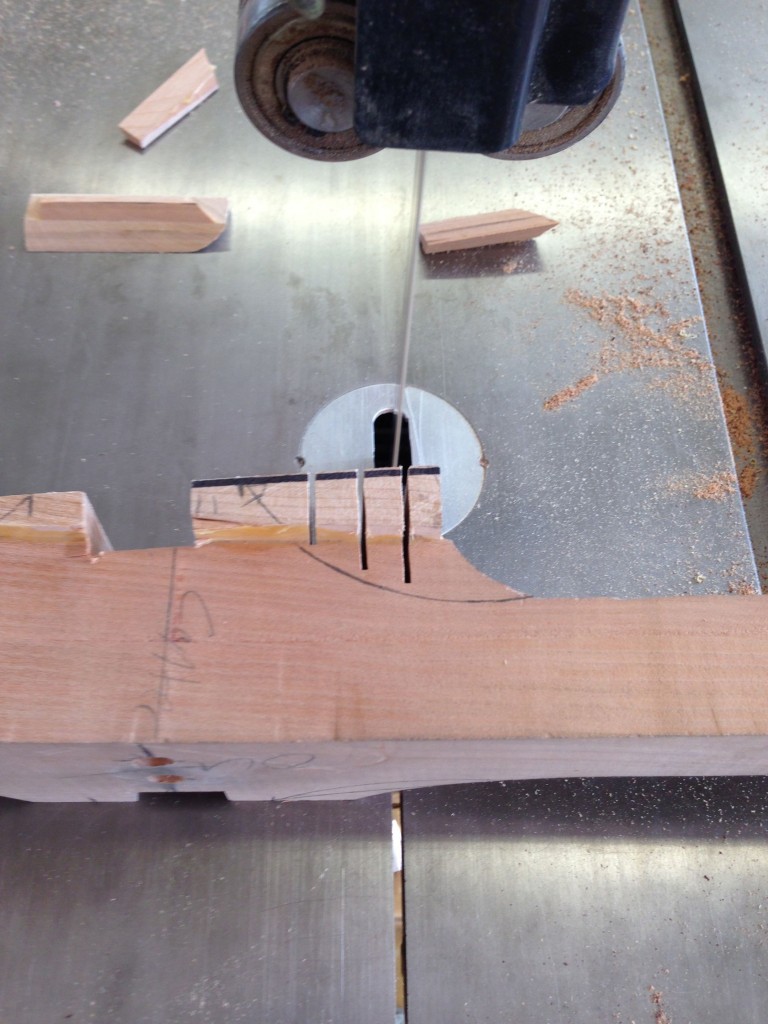

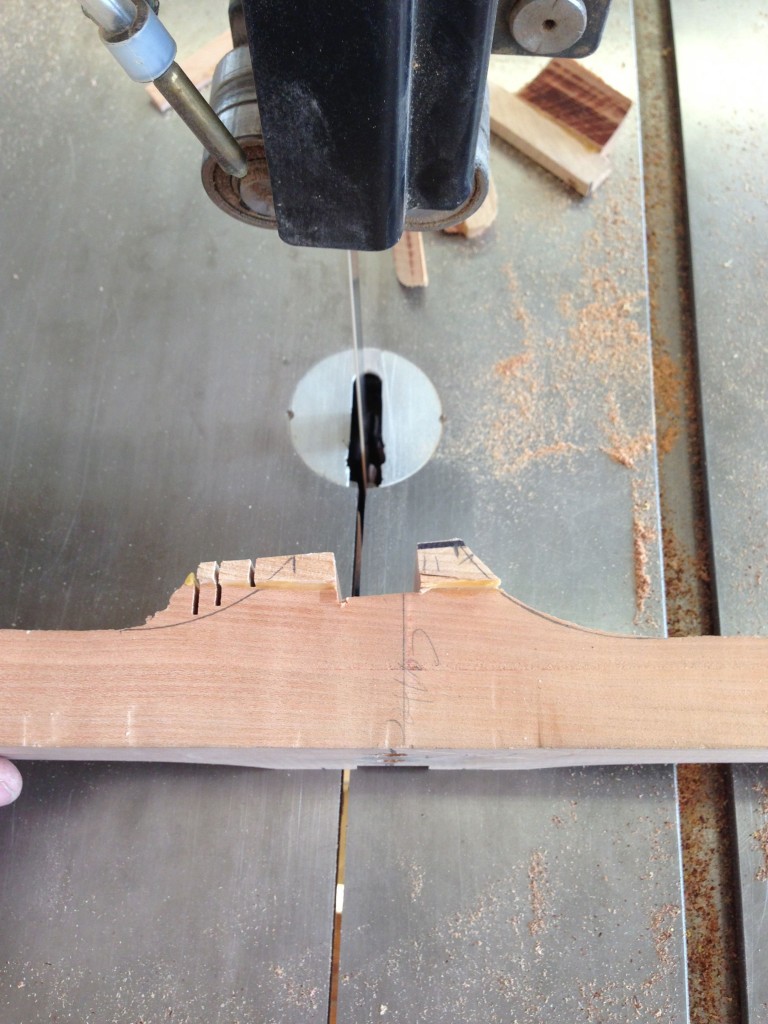

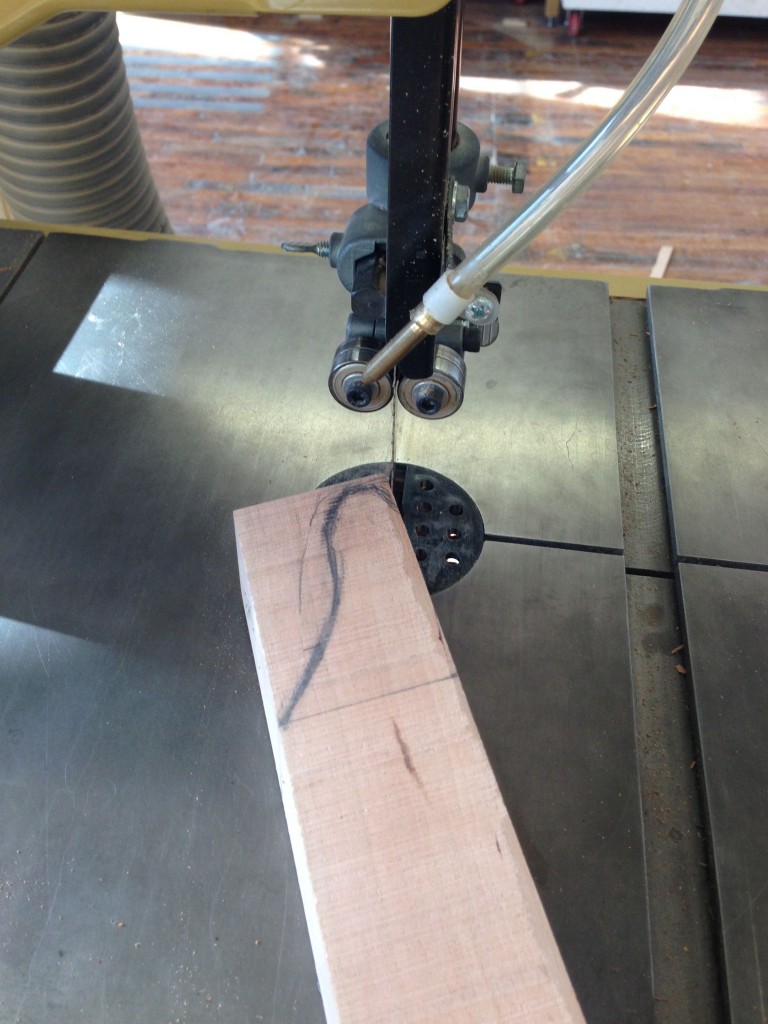

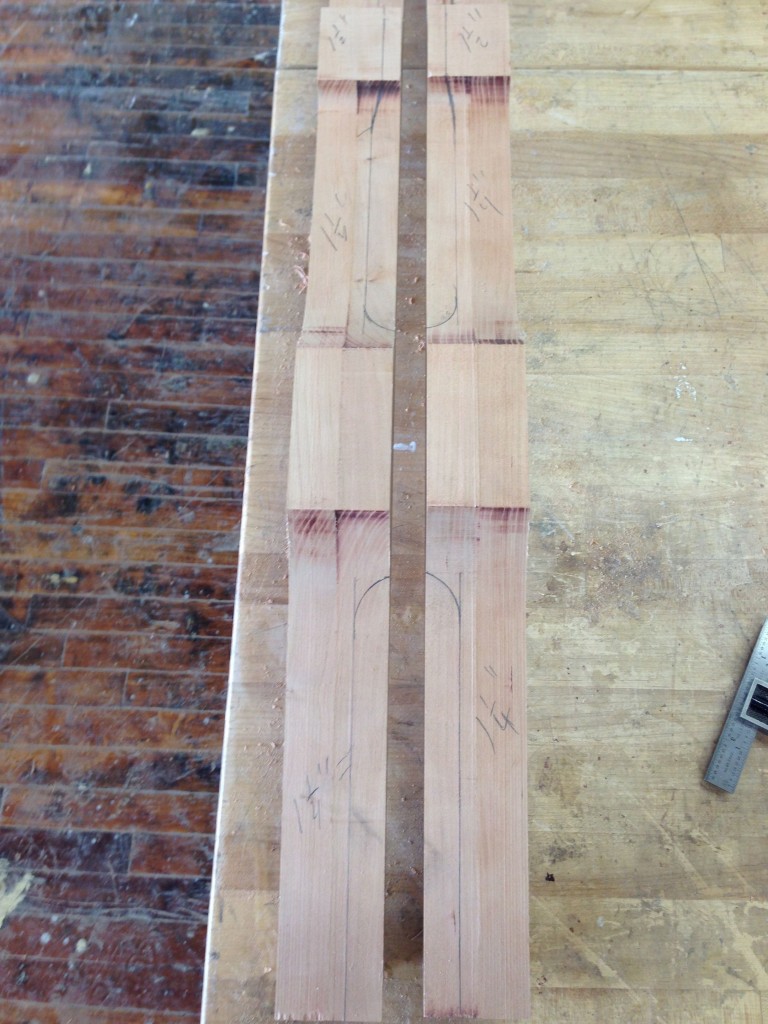

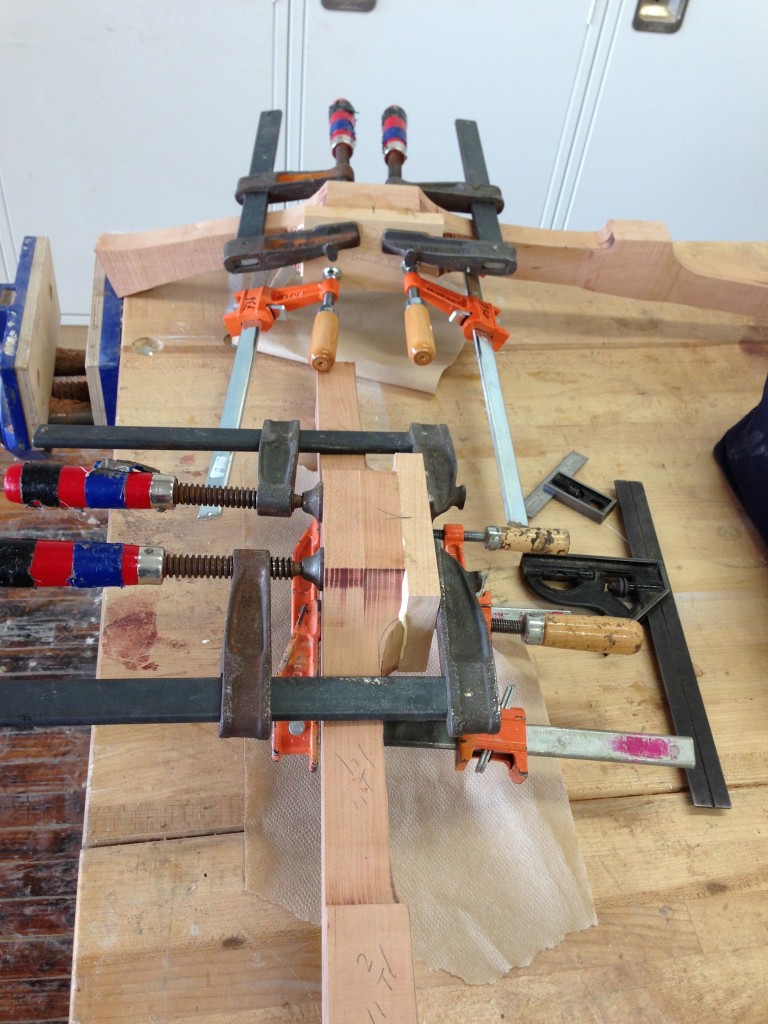

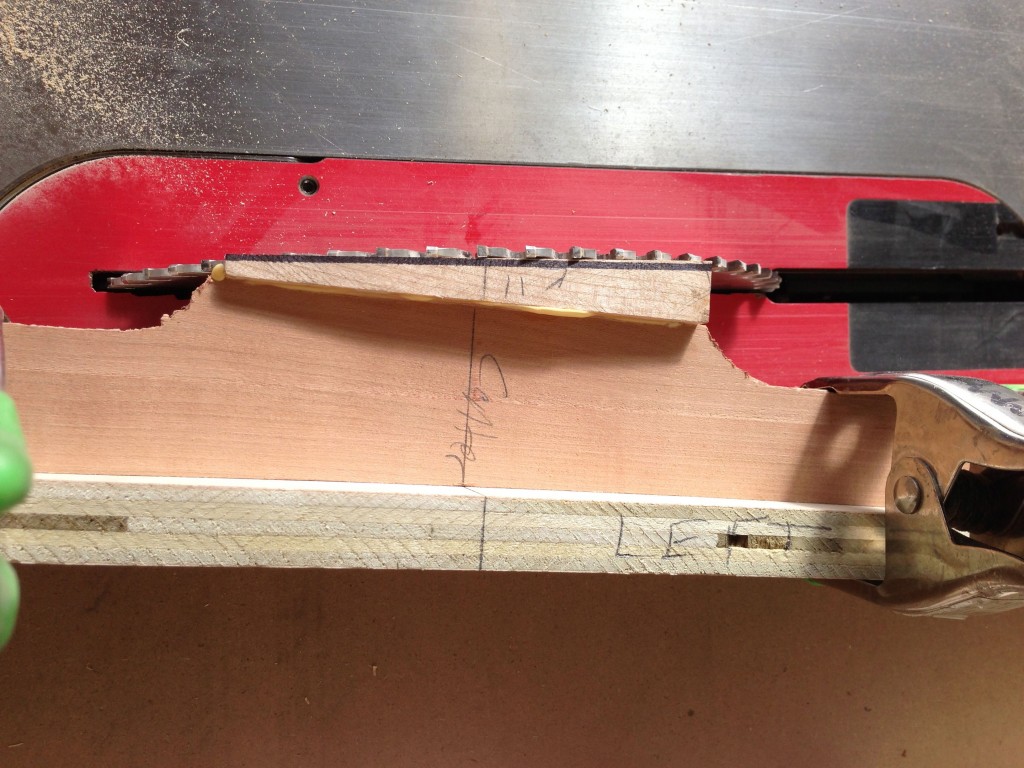

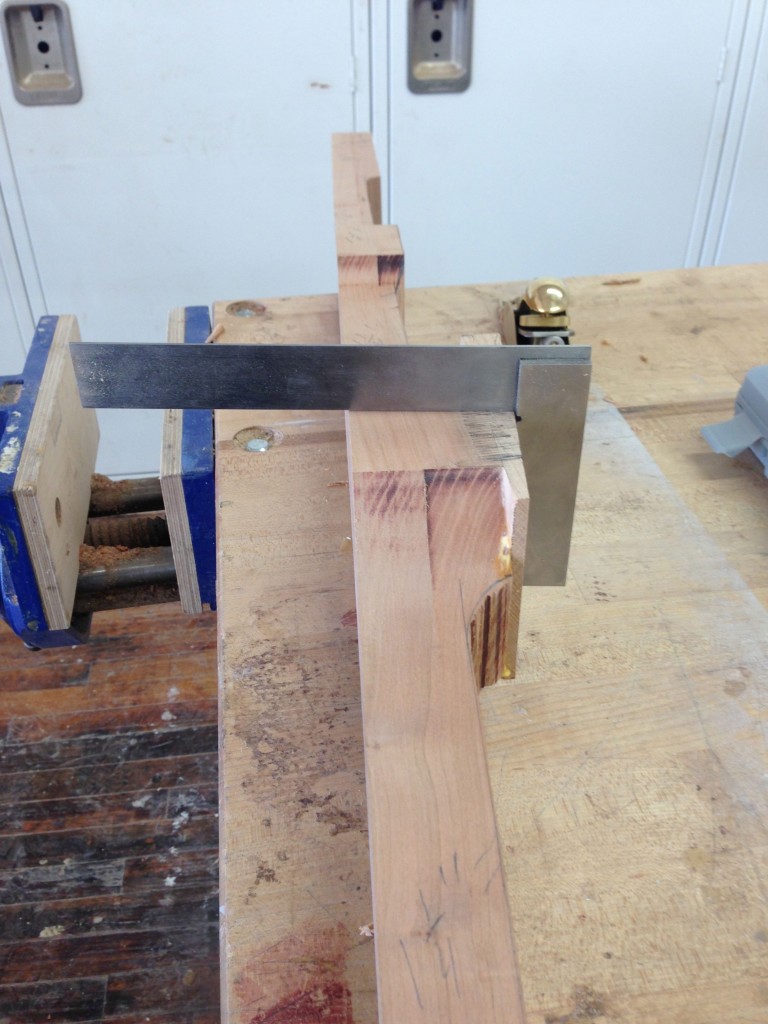

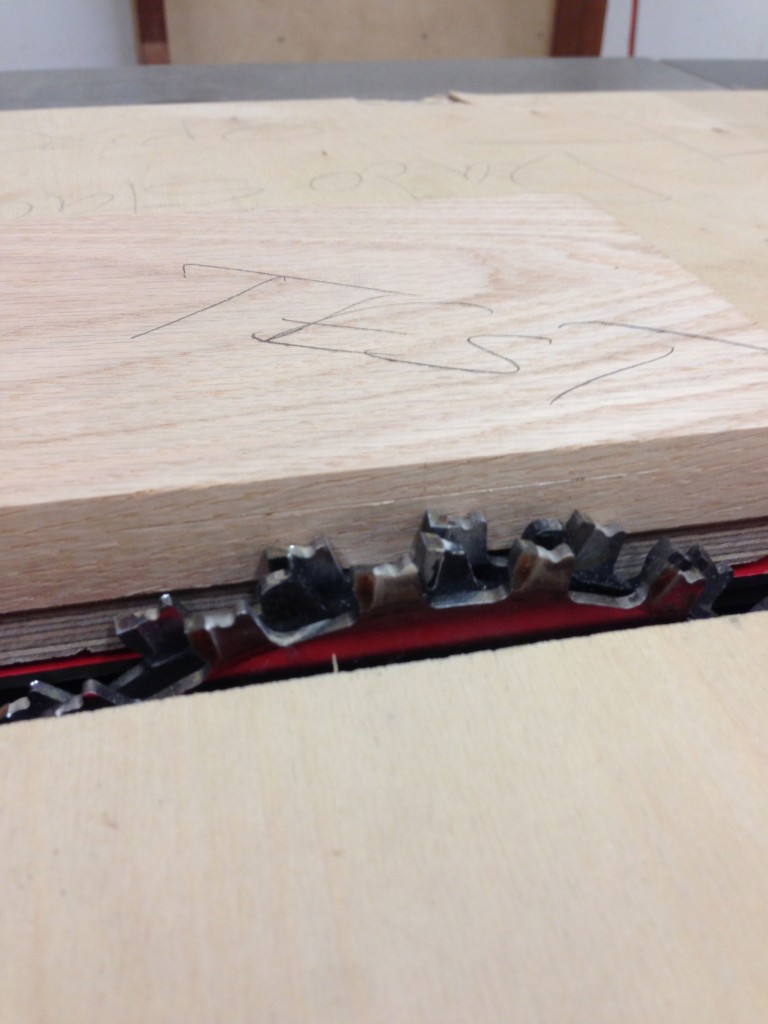

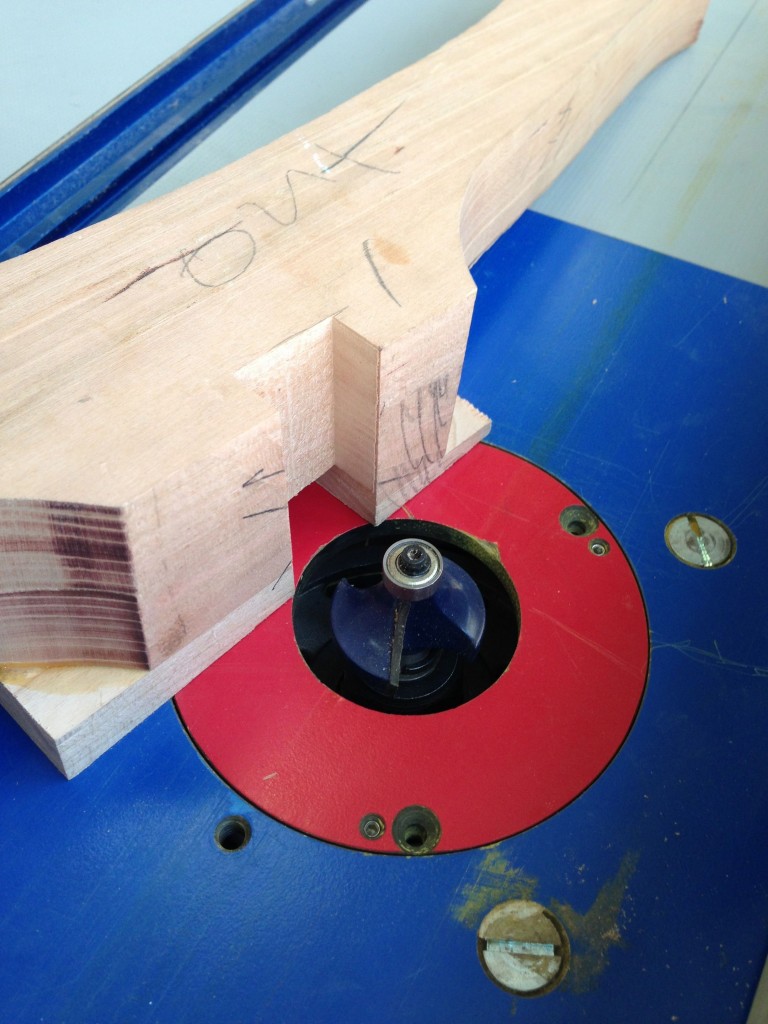

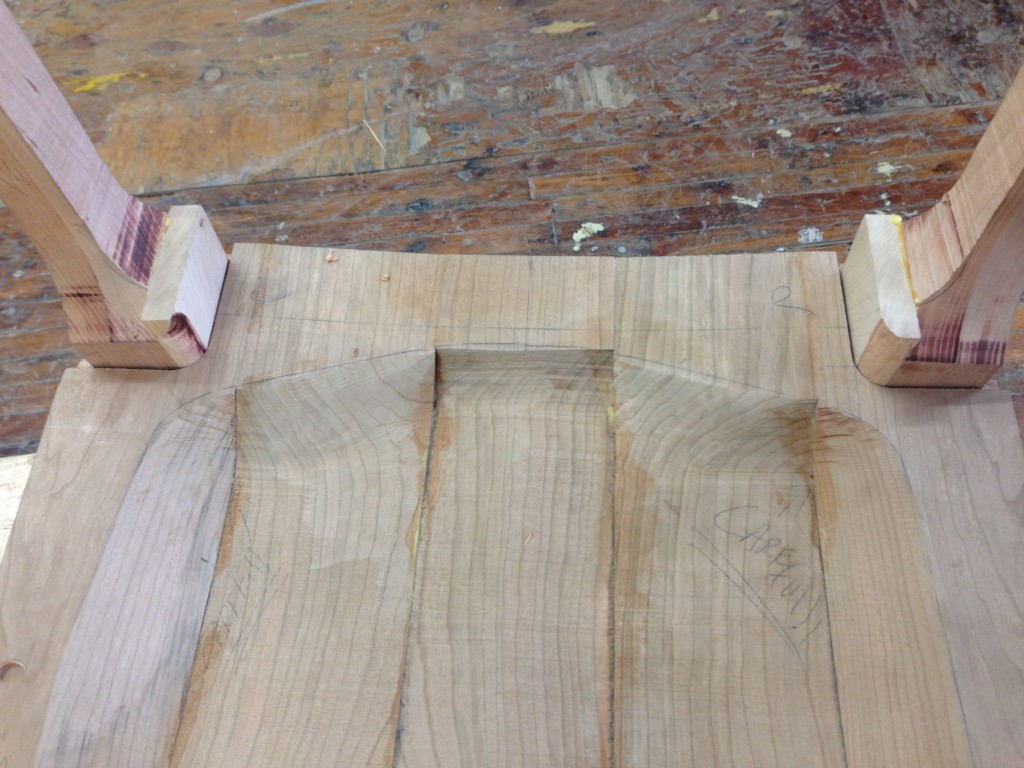

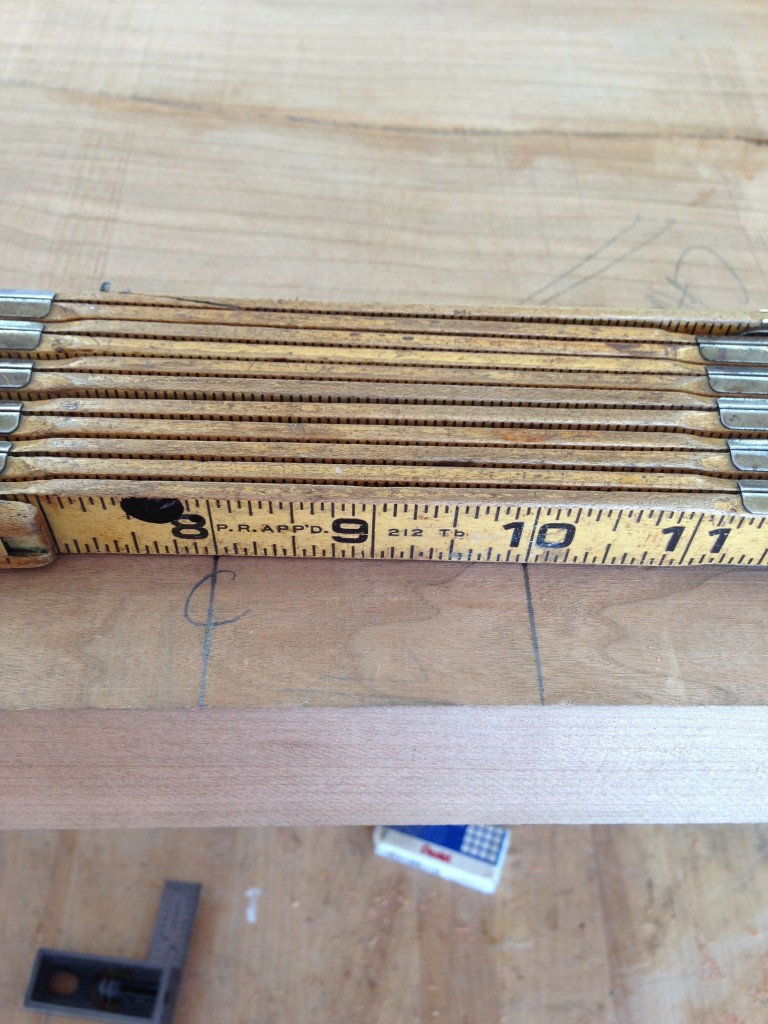

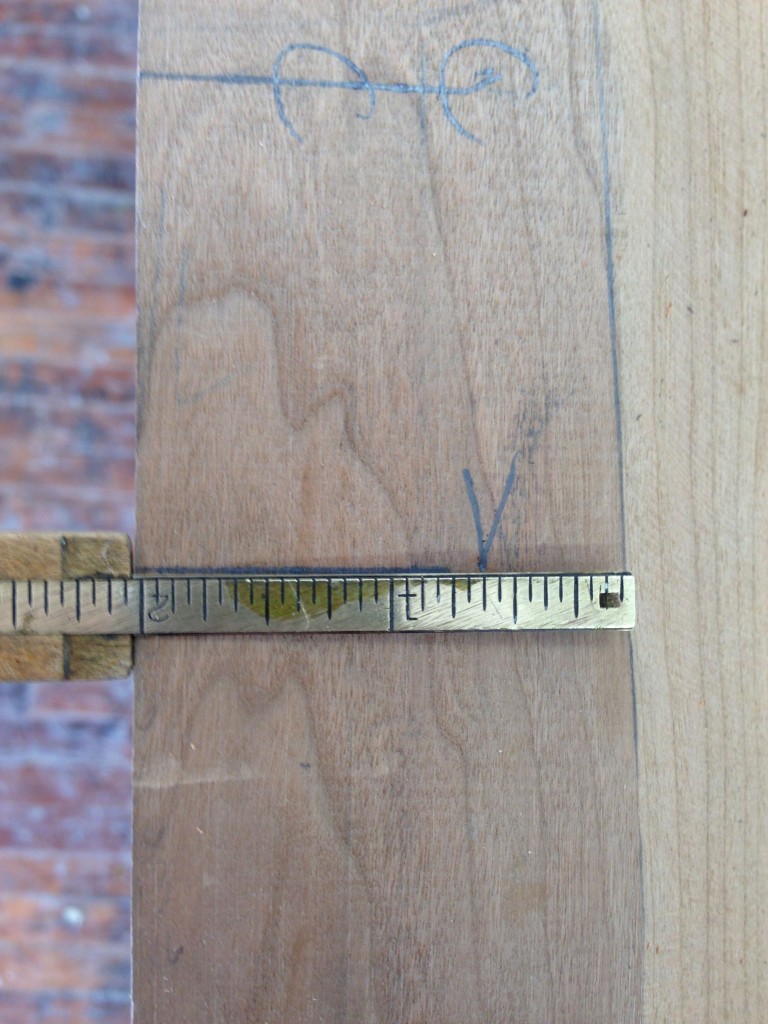

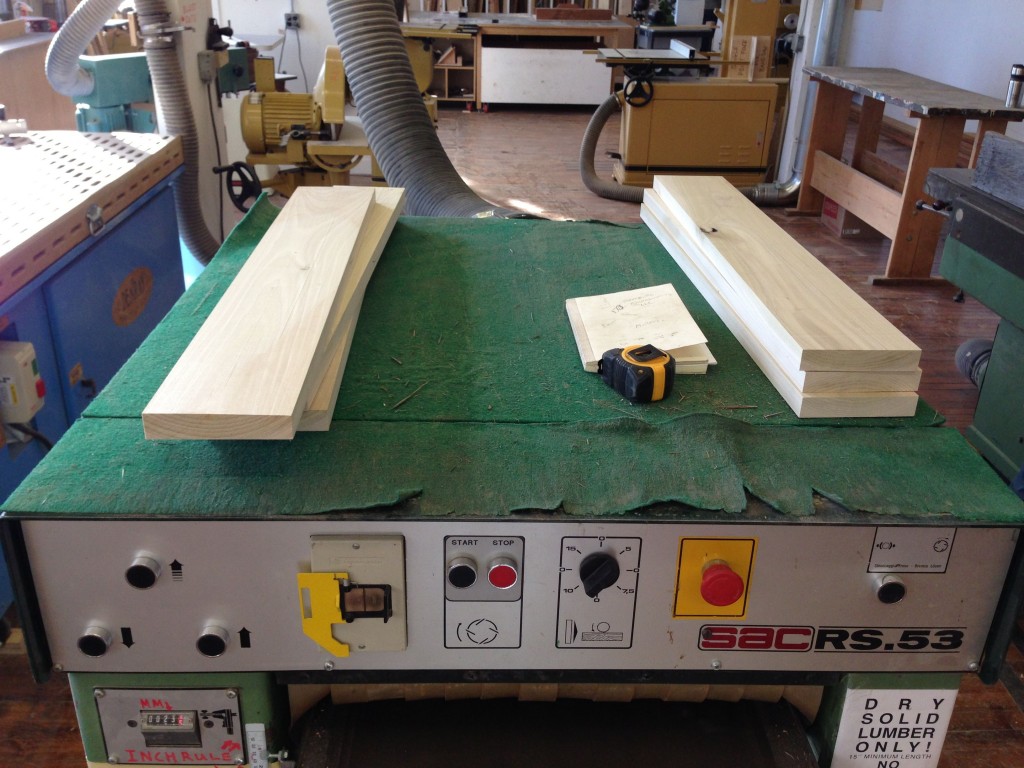

Another table top for SAW. This top features three of the five sections of lumber being butted together in order to create the final 60″ length. This type of construction requires some thought and planning to execute well and create tight joints both along the edge grain and at the end grain. There is also the consideration of where those butt joints occur. I set up the middle two board’s joint to occur at the center point. The two adjoining joints are evenly measured off that point and creates a step look that is mirrored when viewed from the other side of the table.